3D Printed Corneas Could Reduce the Wait for a Corneal Transplant

By Dawn Allcot

Patients requiring a corneal transplant wait an average of six years or more for a cornea donation. Current artificial corneas do not incorporate well with the eye or are not transparent after implantation, making them a less-than-suitable alternative.

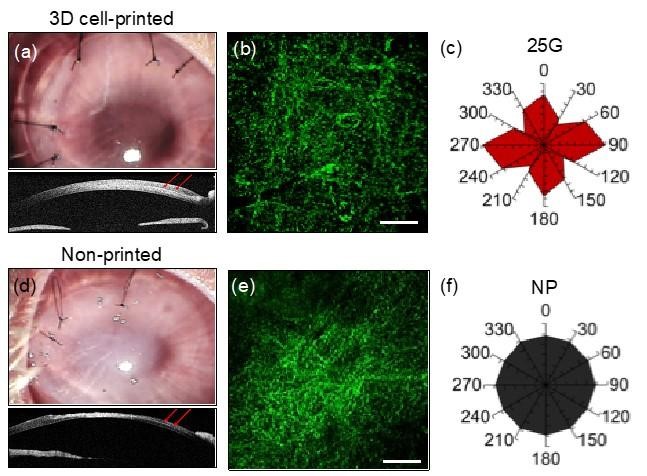

New 3D printed corneas developed by researchers at Pohang University of Science & Technology are biocompatible and transparent after implant. Using bio-ink made of decellularized corneal stroma and stem cells, the artificial cornea recapitulates the corneal microenvironment, making it more like a real human cornea.

The cornea is a thin outermost layer that covers the pupil and it protects the eye from the external environment. It is the first layer that admits light and therefore it needs to be transparent, moves as the pupil moves, and have flexibility.

The human cornea is organized in a lattice pattern of collagen fibrils. The lattice pattern in the cornea is directly associated with the transparency of cornea, and many researchers have tried to replicate the human cornea without success. To successfully create the pattern in the 3D printed cornea, the research team used shear stress generated during the 3D printing process.

When ink in the printer comes out through a nozzle and passes through the nozzle, frictional force which then produces shear stress occurs. The research regulated the shear stress to control the pattern of collagen fibrils.

The research team also observed that the collagen fibrils remodeled along with the printing path create a lattice pattern similar to the structure of native human cornea after four weeks in vivo.

The artificial cornea was developed by Professor Dong-Woo Cho of Mechanical Engineering, Professor Jinah Jang of Creative IT Convergence Engineering, and Ms. Hyeonji Kim at POSTECH, along with Professor Hong Kyun Kim of Ophthalmology at Kyungpook National University School of Medicine.