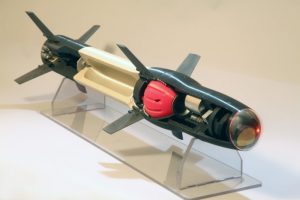

3D-printed missiles soon to be a reality thanks to Raytheon

The future of weaponry may just lie within 3D printers. Well-known defense giant Raytheon has already been tinkering with 3D printed parts for a while and now they have figured out how to 3D print just about 80% of an entire missile.

What good can a 3D-printed missile do? Like anything that is 3D printed, costs are easily reduced, but there are also less piece parts involved which means faster production times and more possibilities for tweaks and improvements. 3D printing in the defense industry means printing parts in hours instead of weeks.

Raytheon Missile Systems engineers have already managed to print almost every guided weapon system component including fins, rocket engines and parts of the guided systems and are currently working on improvements for thermal systems and lightweight structures.

Engineers at the Raytheon University of Massachusetts Lowell Research Institute are also working on printing key radar components that are used in Raytheon missiles like electronic circuits and microwaves.

3D printing would lay down the materials of the circuits required to create an electronic pathway as opposed to current methods of development which include removing materials to create the circuit pathway. “Engineers at the research institute are already able to lay down the conductors and dielectrics needed for printed electronics. They can even lay down carbon nanotubes, tiny structures made of linked carbon atoms, and are working to align them to build futuristic circuits, according to McCarroll,” according to a Raytheon news article.

Once researchers figure out how to print each and every part required for the missile: metallic strongbacks, plastic connectors, semiconductors, energetics and propulsion systems, etc., they will have to figure out how to connect each of the pieces successfully, so there’s still time before soldiers are out in the field printing their own missiles, but Raytheon is getting there.