3D-Printed Nasal Swab Answers COVID-19 Swab Shortage

As soon as COVID-19 testing began, there was a critical shortage of swabs necessary to gather specimens. In response, the Department of Radiology at the University of South Florida (USF) Health in Tampa is designing, developing, and testing swabs they create using a point-of-care 3D printer.

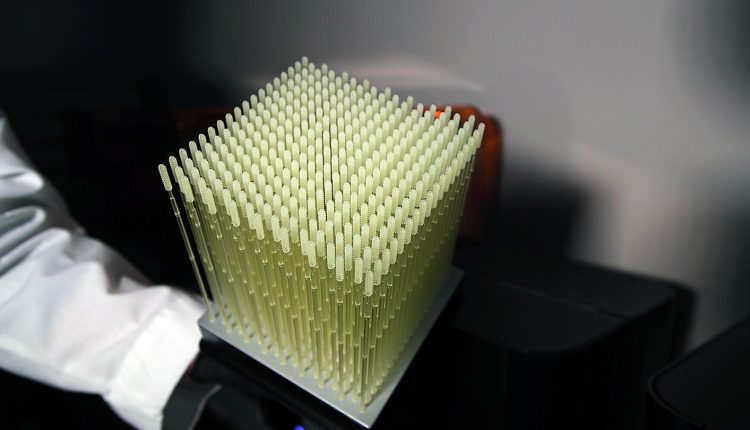

The department has already printed in excess of 100,000 3D NP swabs. They’ve shared the 3D files to hospitals around the world, so that they can print tens of millions more.

Swabs are designed to collect a sample of nasal secretions for analysis from the back of the nose and throat, where COVID-19 appears first. The USF radiology team collaborated with infectious disease, virology, emergency medicine, and radiology colleagues and with Todd Goldstein, Ph.D., at Northwell Health System’s 3D Design and Innovation Lab in New York City. They designed 12 swabs before reaching a final design.

The winning prototype is created using a FormLabs printer. The researchers tested the swabs on 291 hospitalized or emergency-room COVID-19 patients. Tests compared results between flocked swabs and the 3D printed swabs, with identical results.

Depending on the type of 3D printer used, the printing process takes up to 15 hours. After printing, the swabs are rinsed in isopropyl alcohol, cured, and hand-inspected for defects before being sterilized in an autoclave and packed in a test kit.

USF has filed for a provisional patent on the swabs and provided the design files and clinical data at no cost to hospitals, clinics, and licensed medical device companies around the world.

For more information, see https://press.rsna.org/timssnet/media/pressreleases/14_pr_target.cfm?ID=2228.