3D-printed objects sense user’s interaction

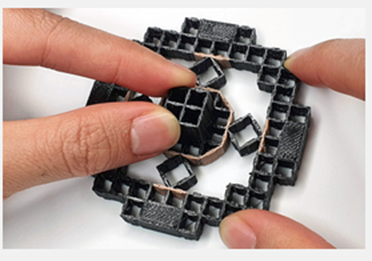

MIT researchers are integrating sensing capabilities into 3D printable structures made of repetitive cells so that designers can rapidly prototype interactive input devices. The new method detects how force is applied to an object and since the structures are made from a single piece of material, they can be rapidly prototyped. Potential applications include such interactive input devices as a joystick, switch, or handheld controller.

The research team integrated electrodes into structures made from metamaterials and created editing software to help build the interactive devices. However, the potential created by integrating sensing directly into the material structure of objects so that they actually sense that interaction, has wide-reaching potential.

Jun Gong, a former visiting PhD student at MIT and now a research scientist at Apple, wrote the paper with fellow lead authors Olivia Seow and Cedric Honnet, of MIT.

Because metamaterials are made from a grid of cells, when the user applies force to a metamaterial object, some of the flexible, interior cells stretch or compress. Researchers successfully created and tested metamaterial joystick and a music controller.

They also developed a 3D editor, MetaSense, that enables rapid prototyping. Users manually integrate sensing into a metamaterial design or they let the software automatically place the conductive shear cells in optimal locations. In the future, researchers want to improve the algorithms behind MetaSense, adding greater sophistication to simulations.

Original Release: Eureka Alert