3D printing speed increased up to 1,000 times

A major technological advance in the field of high-speed beam-scanning devices has increased the speed of 2D and 3D printing by up to 1000 times, according to researchers in Penn State’s College of Engineering.

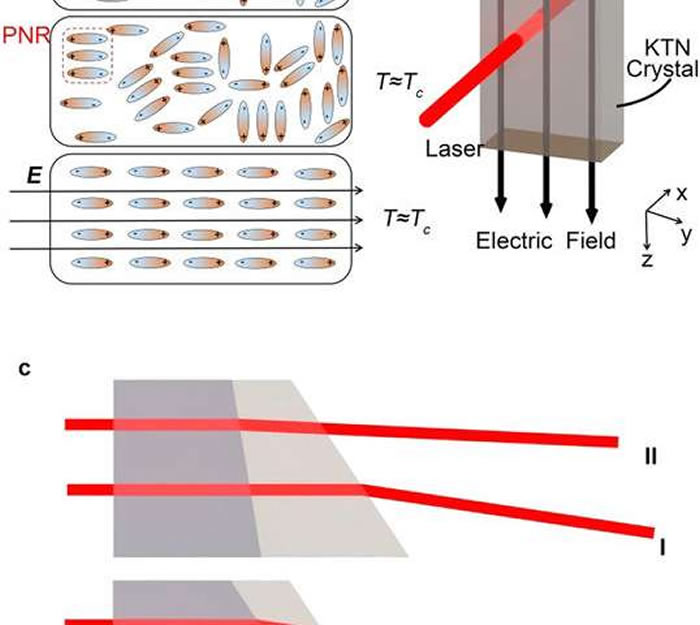

Using a space-charge-controlled KTN beam deflector—a kind of crystal made of potassium tantalate and potassium niobate—with a large electro-optic effect, researchers have found that scanning at a much higher speed is possible.

“Basically, when the crystal materials are applied to an electric field, they generate uniform reflecting distributions, that can deflect an incoming light beam,” said Shizhuo Yin, professor of electrical engineering in the School of Electrical Engineering and Computer Science. “We conducted a systematic study on indications of speed and found out the phase transition of the electric field is one of the limiting factors.”

To overcome this issue, Yin and his team of researchers, Penn State graduate students Wenbin Zhu, Ju-Hung Chao, Chang-Jiang Chen and Robert Hoffman from the Army Research Laboratory in Maryland, eliminated the electric field-induced phase transition in a nanodisordered KTN crystal by making it work at a higher temperature. They not only went beyond the Curie temperature (the temperature in which certain materials lose their magnetic properties, replaced by induced magnetism), they went beyond the critical end point (in which a liquid and its vapor can coexist).

This increased the scanning speed from the microsecond range to the nanosecond regime and improved high-speed imaging, broadband optical communications, and ultrafast laser display and printing.

The group’s findings were published September in an issue of Scientific Reports, a British interdisciplinary journal.

Yin said technology like this would be especially meaningful in the medical industry—high-speed imaging would now be in real-time. For example, optometrists who use a non-invasive imaging test that uses light waves to take cross-section pictures of a person’s retina, would be able to have the 3D image of their patients’ retinas as they are performing the surgery, so they can see what needs to be corrected during the procedure.

Yin added that this research could benefit everyone, in that something being printed in 3D that once took an hour would now take seconds, and 20,000 pages printed in 2D would take one minute.

More information: EurekAlert!

Comments are closed, but trackbacks and pingbacks are open.