Scientists at the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) have been able to observe what exactly happens inside a cathode particle as lithium-ion batteries are charged and discharged, using advanced imaging techniques.

In a research project led by Berkeley Lab materials chemist Guoying Chen, the researchers uncovered important insights into reactions in cathode materials, including the discovery of particle cracking as the cathode is charged, which can reduce battery capacity and life. The research was published today in the journal Nature Communications in an article titled, ‘Phase Transformation Mechanism in LiMn1.5Ni1.5O4 Cathode Particles Revealed by Single-crystal Hard X-ray Microscopy’.

“Understanding dynamic reaction pathways in solid matter and the phase transformation mechanism is extremely difficult but critical in designing advanced materials—not just battery cathodes but materials for other applications as well,” Chen said. “The uniqueness of this work was the combination of using high-resolution two-dimensional and three-dimensional imaging techniques on single-crystal materials.”

Phase transformation—which occurs when lithium comes out of the particles as the battery is being charged or goes back in when discharged—holds the key to how fast and how many times a battery can be cycled.

For this work, Chen chose to use a lithium manganese nickel oxide cathode because it is viewed as one of the next gen battery materials. “Its higher energy comes from its unique high charge and discharge voltage, but the high voltage also provokes enhanced reactivity from the electrolyte and leads to a less stable battery,” she said.

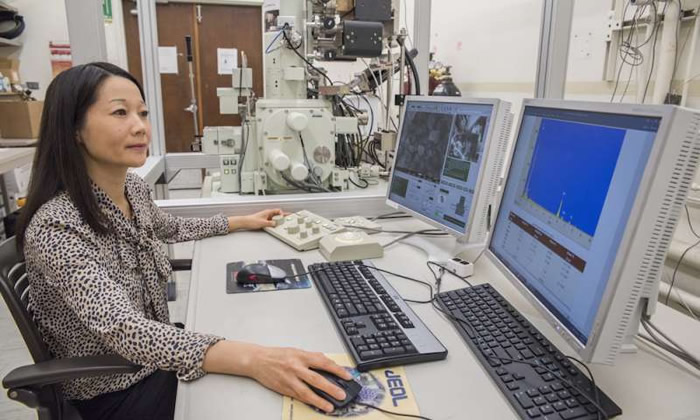

Using transmission microscopy imaging combined with X-ray absorption analysis, they looked at a series of samples they had prepared in the lab. “Instead of using commercial grade particles, which often have built-in variations, we made single crystals in the lab of a few microns in size,” she said. “With our samples we could carry out analysis based on observation of individual particles without worrying about contributions from other random factors not in our control, such as grain boundaries and porosity.”

The researchers mapped out the chemical and phase distribution on their particles at a very high spatial resolution. These maps provide ‘fossil evidence’ of the phase transformation, which allowed them to achieve unprecedented mechanistic understanding of the electrode material.

What they saw was a unique nucleation and growth process involving multiple phases simultaneously on the same particle. The impact of the volume differences between the phases, a reduction of more than 6% in total, caused the particles to crack. This becomes more significant as the particle approaches the fully delithiated state.”

The cracking, Chen asserts, is likely one of the leading causes of the fade in long-term battery cycling that researchers have seen with this cathode. “If you have cracking, it means fresh surface keeps getting exposed, thus causing more reactions with the electrolyte, which consumes the electrolyte and reduces the lifetime of the battery,” Chen said. “If we can minimize or eliminate the cracking issue, we probably will see much improved stability.”

The researchers are examining two ideas to minimize the cracking, using smaller particles and avoiding fully charging the particles. “Reducing particle size can be tricky as it also increases the surface area,” Chen said. “Higher surface area means more side reactions to begin with, so it is important to find the optimal size.”

Meanwhile Chen said her group is also looking for other approaches for high-energy batteries, such as materials that can provide a high capacity. “The approach we developed here is broadly applicable for designing and optimizing both new and existing electrode materials,” she said.

More information: Phys.org