Multi-junction solar cells are both the most efficient type of solar cell on the market today and the most expensive type of solar cell to produce.

But now, researchers from North Carolina State University put together a proof-of-concept approach for creating multi-junction solar cells using off-the-shelf components, which would ultimately result in lower cost, high-efficiency solar cells for use in multiple applications.

Multi-junction, or stacked, solar cells are currently the most efficient cells on the market. They convert up to 45% of solar energy they absorb into electricity. The cells are constructed by stacking semiconductors with varying bandgaps on top of one another, which allows the cell to absorb different wavelengths of solar radiation. However, these cells are much more expensive to produce than less efficient thin solar films.

“We want to create high-efficiency solar cells at a reasonable cost,” said Salah Bedair, Distinguished Professor of Electrical and Computer Engineering at NC State and lead author of the research.

So the team explored silicon as an option. “Silicon-based thin solar cells are very popular because the material has around 20% efficiency and the cells cost about 1/10th what a multi-junction solar cell costs. And other, lower cost, lower efficiency materials are gaining popularity as well. If we could create stacked solar cells using this existing technology we would be well on our way to reaching our goal,” she said.

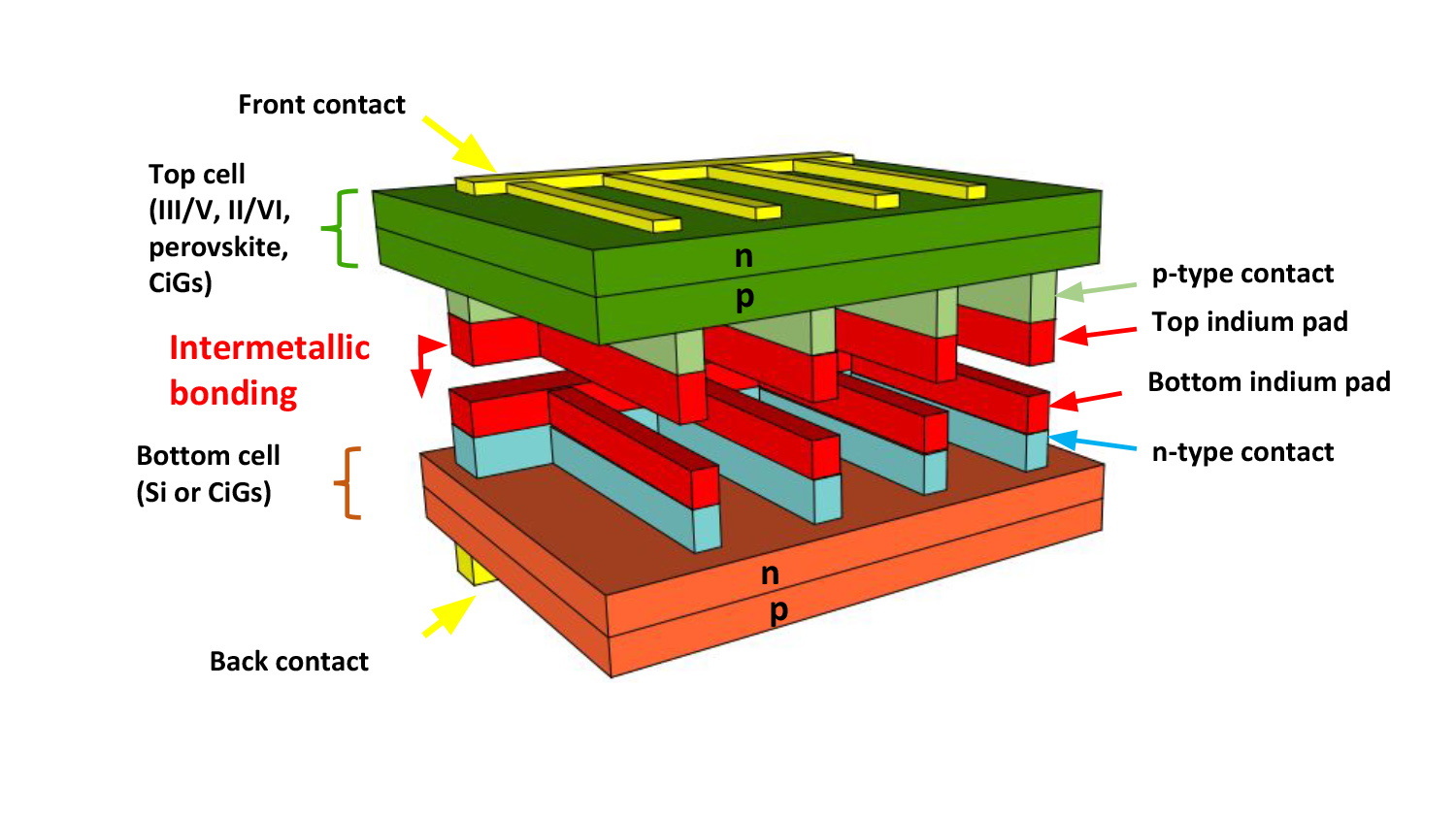

The problem is, you can’t just stack different solar cells on top of each other because the different materials are structurally incompatible, and so charges cannot pass through them to be collected. To solve that problem in current multi-junction solar cells heavily doped metals are used to create a tunnel junction between the various layers – adding significant expense and complexity to the multi-junction solar cell’s creation.

The simpler approach utilizes intermetallic bonding to bond solar cells made of different materials. In a proof-of-concept, the team stacked an off-the-shelf gallium arsenide solar cell on top of a silicon solar cell.

“In multi-junction solar cells the tunnel junction enables electric connectivity by acting as a metal-to-metal connection,” said Bedair. “In our system, indium serves as a shortcut to that. The existing metal contacts of the individual cells are covered with indium films. The indium films bond to themselves easily at room temperature under low pressure. The result is a solar cell made of two different materials that is mechanically stacked and electrically connected.

“With this technique, we are able to take advantage of inexpensive, off-the-shelf solutions without having to develop all new technology. Manufacturers could simply tweak their existing products slightly to increase their efficiency in multi-junction solar cells, rather than having to create new products.”