Active-S Humidity Control Sheets Protect Sensitive Equipment in Enclosures from Excess Moisture

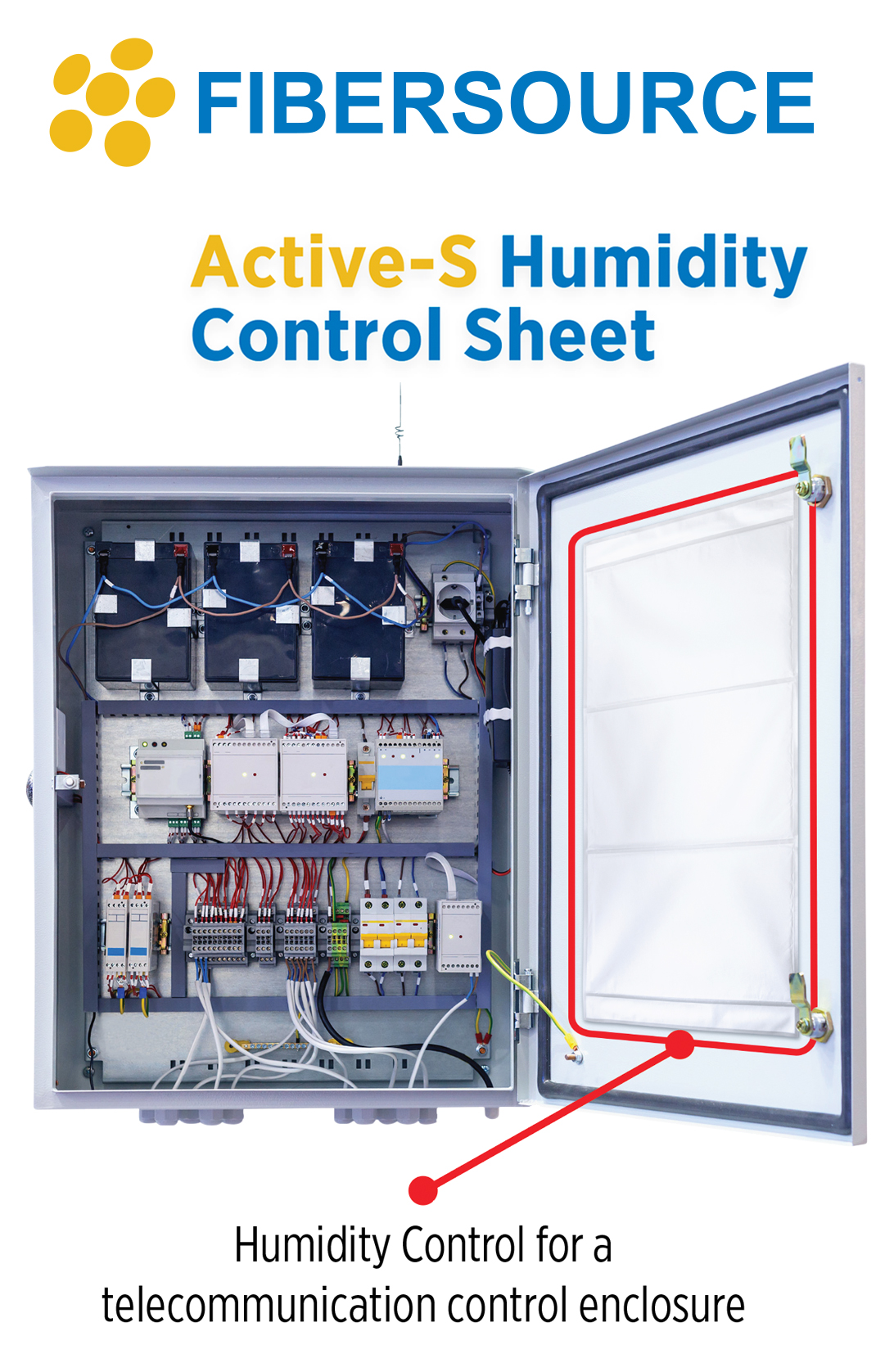

FiberSource now offers Active-S Humidity Control Sheets, a maintenance-free alternative to desiccants, heaters, dehumidifiers, thermostats, hygrotherms, hygrostats, and corrosion inhibitors for preventing excess moisture in cabinets, enclosures, and cases. Originally developed to protect the sensitive in-field equipment of a Japanese telecom provider, the sheets are easy to apply and ideal for tight and hard-to-reach spaces as well as curved surfaces.

“Active-S Humidity Control Sheets have proven their dependability and value time and again in 10 years of field application,” says Brian DiMarco, President, FiberSource. ”More than 1.6 million pieces are installed in connection terminal boxes and protection devices, and their track record is perfect—so much so that they’ve been endorsed repeatedly by contractors in the telecommunications industry in Japan.”

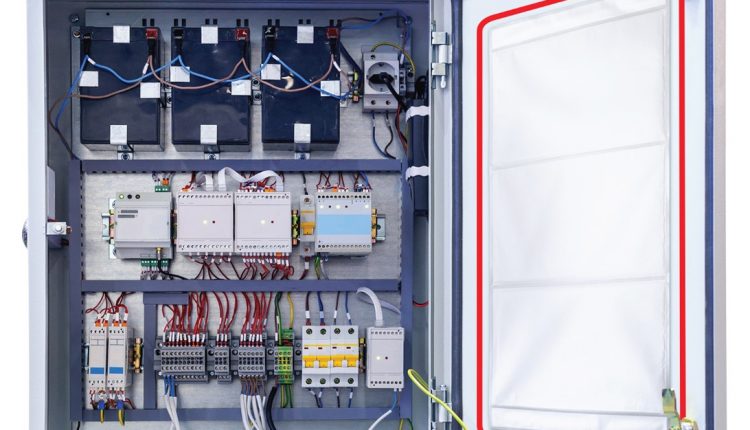

Although cabinets and enclosures are designed to protect sensitive components and systems, it can be challenging to prevent moisture from collecting and forming condensation, even in sealed enclosures. Opening and closing doors for maintenance, factory wash down applications, and temperature fluctuation can create condensation that may cause corrosion of components, increased electrical resistance, decreased component performance, short circuits, potentially dangerous arcing and sparking, and degradation of electrical wire insulation.

Active-S Humidity Control Sheets are made of a macromolecule polymer, which is a super-absorbent material that “breathes,” providing an active exchange of absorption and release. When humidity in the enclosure is high, the humidity control sheet absorbs the excess moisture, reducing humidity levels inside the cabinet. But when the cabinet becomes dry, the sheet “breathes out” the moisture, maintaining relative humidity at or under 60% in the cabinet.

The water absorption capability of a desiccant, on the other hand, is dependent on a variety of factors, including desiccant type, humidity, and temperature. For example, silica gel can absorb up to 40% of its weight in water. A 4’x6’x2’ electrical enclosure in a hot/humid environment would saturate 125g of desiccant in about two air exchanges, requiring frequent desiccant change-outs and driving up maintenance costs.

Active-S also is cost-effective compared to other solutions that require more space, maintenance, as well as a power source. Active-S Humidity Control Sheets are a more practical and reliable solution than these alternatives: The Active-S sheets last for years, can be applied in minutes in tight and hard-to-reach spaces, fit all sizes of enclosures, and require no power source to maintain humidity levels.

“The ease of installation and long product lifetime significantly reduce time and labor costs,” says DiMarco. “Active-S Humidity Control Sheets offer the lowest installation cost, and lowest applied cost for controlling humidity.”

The flexibility and dependability of the sheets make them an ideal solution for a wide range of applications including communications equipment, control panels, utilities, traffic controls, M2M and IoT devices, construction equipment, drones, marine enclosures and food and beverage equipment.

The Active-S Humidity Control Sheets are available in four sizes, with cost starting at $15 per sheet. For more product information, call 864-277-7200 or 888-342-3776, email [email protected], or visit www.active-sfibersource.com.