Researchers mimic Kirigami folds for complex 3D nanostructures

The ancient Japanese art of kirigami offers a way to fabricate complex 3D nanostructures for electronics, manufacturing and health care applications. Kirigami enhances Japanese origami, the art of folding paper to create 3D structural designs, by strategically incorporating cuts to the paper before folding.

Daniel Lopez, Penn State Liang Professor of Electrical Engineering and Computer Science, is the leader of the team that published recent research in Advanced Materials. According to Lopez, 3D structures are difficult to fabricate because current nanofabrication processes are based on the technology used to fabricate microelectronics which only use planar, or flat, films.

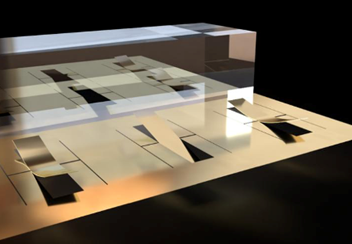

Strategically placed cuts to structural films can create 3D nanostructures when force is applied to the films, similar to how kirigami cuts made to paper can create pop-up structures.

When cuts are introduced and forces are applied in a certain direction, a structure pops up, and the geometry of the planar pattern of cuts determines the shape of the 3D architecture. Their work demonstrates nanoscale devices that can tilt or change their curvature just by changing the width of the cuts a few nanometers. Kirigami-style nanoengineering enables development of machines and structures that morph in response to changes in the environment. An example is an electronic component that changes shape in elevated temperatures so that more air flow within a device to keep it from overheating.

The technique is expected to enable further development of adaptive flexible electronics that can be incorporated onto surfaces with complicated topography, such as a sensor resting on the human brain. Lopez said his goal is to work with other researchers at Penn State’s Materials Research Institute (MRI) to develop a new generation of miniature machines that are atomically flat and are more responsive to changes in the environment.

Original Source: Eureka Alert