Using ML in discovery of new materials for 3D printing

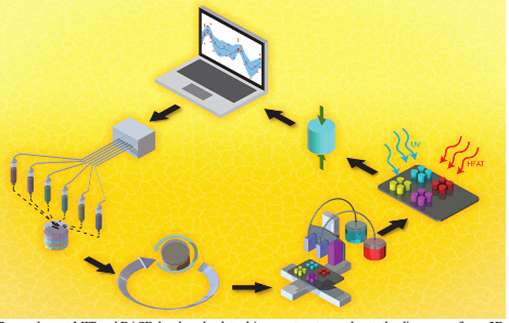

The use of 3D printing across multiple manufacturing segments is creating greater demand for new 3D printing materials designed for very specific uses. This discovery, however, takes an inordinate amount of time. Researchers at MIT have developed a data-driven process using machine learning to optimize new 3D printing materials with such multiple characteristics as toughness and compression strength.

Streamlining materials development lowers costs and lessens the environmental impact of chemical waste.

Researchers used an optimization algorithm that performs much of the trial-and-error discovery process and created a free, open-source materials optimization platform called AutoOED that incorporates the algorithm. AutoOED is a full software package that also allows researchers to conduct their own optimization.

So far, they used the system to successfully optimize formulations for a new 3D printing ink that hardens when it is exposed to ultraviolet light. The algorithm identified 12 top performing materials after testing only 120 samples.

The system encourages exploration, which could be especially useful in situations when specific material properties can’t be easily discovered intuitively. Expectations are that automation will speed the process even more in the future.

Original Release: MIT