3D Ice Printing—Artificial Blood Vessels in Engineered Tissue

3D printing may have found a new niche—creating a template for artificial blood vessels in engineered tissue using ice. Artificial organ transplants and drug testing are two possible applications.

Given that the demand in the U.S. for organs, such as hearts, kidneys, and livers, far exceeds the available supply, approximately 6,000 Americans die while waiting each year.

The challenge with creating lab-grown organs and tissues is creating blood vessel networks to work like natural ones, from tiny capillaries to larger arteries. To date, artificial blood vessel designs typically don’t function properly in the body.

The possibility of using 3D ice printing to help create blood vessels in the body is being demonstrated at the 68th Biophysical Society Annual Meeting in Philadelphia, Pennsylvania.

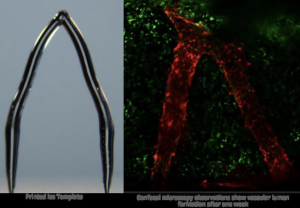

3D ice printing involves adding a stream of water to a very cold surface. Instead of letting the water completely freeze while printing, it is in a liquid phase on top. This achieves a very smooth structure without a layering effect. The heavy water used has hydrogen atoms replaced by deuterium for a higher freezing point.

The 3D-printed ice templates are then embedded in a gelatin material, GelMA. When exposed to UV light, the gelatin hardens, and the ice melts, leaving realistic blood vessel channels behind. So far, the cells survived on the gelatin for up to two weeks.