How 3D Printed Brain and Cartilage Change the Medicine Game

Imagine a future where the lines between life and technology blur, where 3D printers, known for crafting everything from simple household items to complex mechanical parts, hold the power to redefine the landscape of medical science. This is not a distant reality, but today’s groundbreaking advancement, as recent innovations in 3D-printed tissue from the University of Wisconsin-Madison and TU Wien (Vienna), promise to revolutionize healthcare and treatment methodologies. These aren’t just incremental steps forward; they are giant leaps in our quest to understand and heal the human body in ways previously confined to the realms of science fiction.

At the heart of these innovations lies the potential to transform lives and provide hope where traditional medicine has reached its limits. Developing 3D-printed brain tissue that behaves like its natural counterpart opens new frontiers in the battle against debilitating neurological and neurodevelopmental disorders. Meanwhile, the ability to create replacement tissue for injured cartilage offers a glimpse into a future where the regeneration of complex tissues and organs is a reality, drastically reducing the need for organ transplants with their associated challenges.

The University of Wisconsin-Madison has made a significant leap forward by developing the first 3D-printed brain tissue that mirrors the growth and functionality of natural brain tissue. This pioneering work is spearheaded by Su-Chun Zhang, a professor of neuroscience and neurology at UW-Madison’s Waisman Center, and his team. Their novel approach to 3D printing, which involves laying brain cells horizontally in a softer “bio-ink,” has enabled the creation of tissue that holds together and allows neurons to intertwine and communicate effectively. This technique represents a significant advancement in the study of neurological and neurodevelopmental disorders, offering a new model to explore the complexities of the human brain, from the molecular mechanisms of development to the pathogenesis of disorders like Alzheimer’s and Parkinson’s disease.

The precision of this method allows for the creation of specific brain regions, such as the cerebral cortex and striatum, facilitating detailed studies on cell signaling and interactions. This could lead to better understanding and treatments for various conditions, providing a powerful tool for drug testing and studying disease progression and treatment effects within accurately replicated human brain networks.

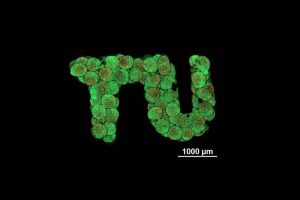

On the other hand, TU Wien has focused on creating replacement tissue for applications such as repairing injured cartilage, a challenge that has puzzled researchers for years. Led by Oliver Kopinski-Grünwald and Prof. Aleksandr Ovsianikov, the team has employed a high-resolution 3D printing process to construct tiny, porous spheres out of biocompatible and degradable plastic, which are then populated with cells. These spheroids can be assembled into any desired shape, merging seamlessly to form a uniform, living tissue. This method overcomes the limitations of traditional stem cell cultivation, offering control over the shape and density of the resulting tissue, which is critical for cartilage and potentially other tissues like bone.

Credit: TU Wien

The innovative use of 3D-printed micro-scaffolds provides the necessary mechanical stability for the tissue as it matures and allows for the precise degradation of the scaffold material, leaving behind functional tissue in the exact desired shape. This advancement holds great promise for regenerative medicine, enabling the production of tailor-made tissue implants for cartilage repair.

These advancements showcase the intersection of engineering and medical science, where 3D printing technology opens up new avenues for research and treatment. The University of Wisconsin-Madison’s brain tissue model offers a new way to understand and treat neurological conditions. In contrast, TU Wien’s cartilage tissue technique paves the way for customized tissue implants. These breakthroughs demonstrate the versatility and potential of 3D printing in the medical field and hint at a future where the regeneration of complex tissues and organs becomes a routine part of medical care.

As these technologies continue to develop, the implications for the medical and engineering industries are profound. The ability to print functional tissue on demand could drastically reduce the need for organ transplants, eliminate testing on animals, and accelerate the development of treatments for a wide range of diseases. Furthermore, the collaboration between engineers and medical professionals in these projects highlights the interdisciplinary nature of modern medical research, promising a future where such synergies lead to even more innovative solutions to some of humanity’s most pressing health challenges.