Heavy-Hitting Battery Enables Light, Energy-Efficient Vehicles

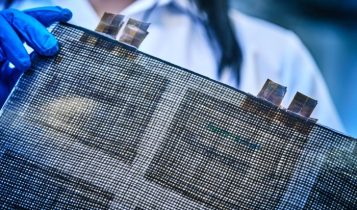

A Chalmers University of Technology research team created a battery from a carbon fiber composite with aluminum stiffness characteristics and sufficient energy density for commercial use. They followed the basic concept of building with a material that functions as both a battery and a load-bearing structure. The team claims it is a world-leading advance in massless energy storage, where a structural battery could halve the weight of a laptop, make the mobile phone as thin as a credit card, or increase the driving range of an electric car by up to 70% on a single charge. They published “Unveiling the Multifunctional Carbon Fibre Structural Battery” in Advanced Materials.

The team has been at it for a while. A previous milestone, reached in 2021, produced a battery with an energy density of 24 watt-hours per kilogram (Wh/kg)—20 percent capacity of a comparable lithium-ion battery. Currently, it’s at 30 Wh/kg. The battery is part of the construction and is also made of a lightweight material, reducing the vehicle’s weight.

To meet vehicle safety requirements, the team’s structural battery cell has significantly increased its stiffness, measured in gigapascal (GPa), from 25 to 70. The material carries loads comparably to aluminum but with a lower weight.

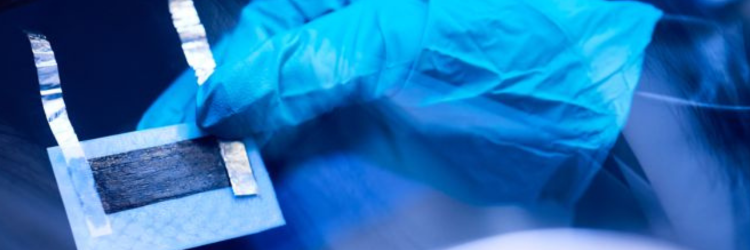

CREDIT: Chalmers University of Technology | Henrik Sandsjö

The developed battery uses a composite material with carbon fiber as both the positive and negative electrodes, coating the positive electrode (the cathode) with lithium iron phosphate.

Here, the carbon fiber is multifunctional. In the anode, it’s a reinforcement, an electrical collector, and an active material. In the cathode, it acts as a reinforcement, a current collector, and a scaffolding for the lithium iron phosphate coating to build on. Lithium ions are transported between the battery terminals through a semi-solid electrolyte instead of a liquid one. The design contributes to increased safety in the battery cell through reduced fire risk.

Commercialization is still a way off, but this building philosophy of batteries as a part of the construction material of a product won’t just be beneficial for electric cars but also for drones, handheld tools, laptops, and mobile phones.