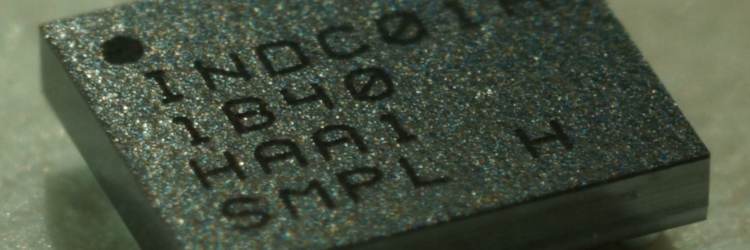

Orca OS2000 Transceiver for Bi-directional Communications Between Sensors, Actuators, and Control Systems

Orca Semiconductor’s new OS2000 IO-Link communications transceiver improves Industry 4.0 intelligence. Enabling seamless, bi-directional communication between sensors, actuators, and control systems, Orca claims improved productivity, efficiency, and downtime reduction on the factory floor. The transceiver can be used in either IO-Link master or device applications.

“We are continuing our aggressive design and delivery of customized, application specific analog products to fill the void neglected by Big Analog,” said Andrew Baker, CEO of Orca Semiconductor. “IO-Link transceivers are the backbone of Industry 4.0, driving intelligence on the factory floor by enabling seamless communication between devices. With increased factory data, manufacturers can boost productivity, reduce downtime, and optimize efficiency, significantly lowering operating costs and creating a more agile, intelligent manufacturing process.”

Features include two control interface options: I2C with control over advanced features and diagnostics, or GPIO. It also includes two linear voltage regulators, one digital input channel, an internal clock generator, and integrated surge protection for input power, CQ, and the digital input channel. The linear 5V voltage regulators may be bypassed by using an external 5V source. The internal clock generator provides an IO-Link timing-compliant clock to the system microcontroller. There are five different output frequency options, so it will work with most microcontrollers. It is designed to be footprint and function compatible with the MAX22515 from Analog Devices, providing an easy, direct replacement in any application.

Orca Semi will demonstrate the OS2000 at the SPS conference, November 12-14, 2024, in Hall 8, stand 210.8