Self-Assembling Electronics: A Breakthrough in Chip Manufacturing

Researchers at North Carolina State University have unveiled a revolutionary technique for self-assembling electronic devices. This innovation, called Directed Metal-Ligand (D-Met) reactions, enables the creation of nanoscale and microscale transistors and diodes without relying on conventional, costly chip manufacturing processes. The method promises high-yield, customizable results, paving the way for complex devices like 3D chips.

How It Works

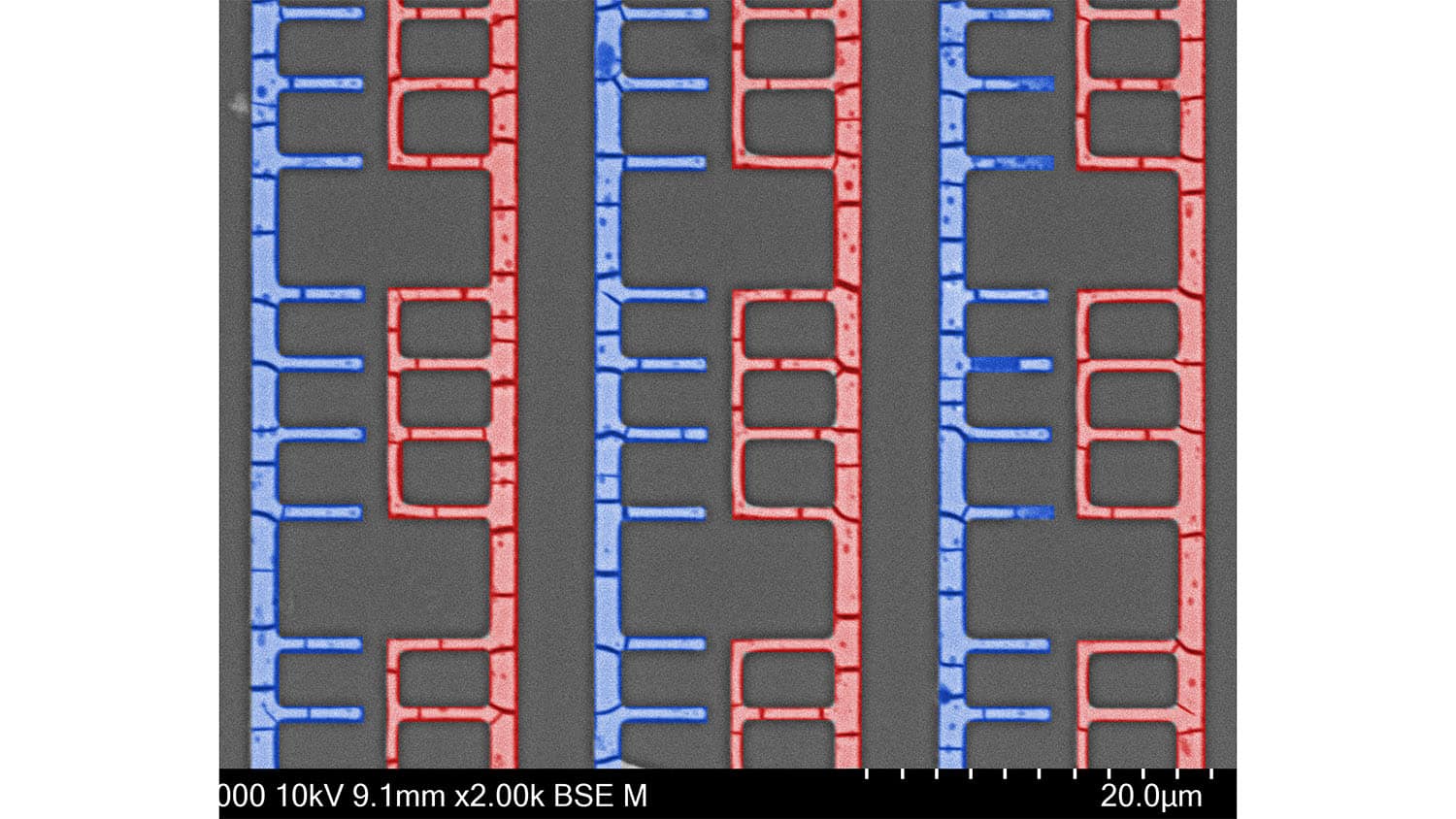

The D-Met process begins with liquid metal particles, such as Field’s metal—an alloy of indium, bismuth, and tin. These particles are paired with a mold that dictates the size and pattern of the final structure. A solution containing carbon- and oxygen-based ligands is poured onto the liquid metal. The ligands extract ions from the metal’s surface, holding them in precise geometric patterns.

As the solution flows into the mold, it starts forming intricate 3D structures. Simultaneously, the liquid portion of the solution evaporates, packing the structures tightly together. The mold constrains the formation, ensuring predictable, symmetrical arrays rather than chaotic patterns.

Once the structure reaches the desired size, it is heated, breaking down the ligands into their carbon and oxygen components. The oxygen reacts with the metal ions to form semiconductor metal oxides, while the carbon creates graphene sheets. This process results in semiconductor structures wrapped in graphene, which can be used for tuning bandgaps and creating photo-responsive properties.

Advantages Over Traditional Techniques

Traditional chip manufacturing is expensive, complex, and time-intensive, often resulting in low yields and significant waste due to faulty chips. The D-Met approach offers several advantages:

- Cost-Efficiency: Simplifies manufacturing steps, significantly reducing expenses.

- High Yield: Consistently produces functional arrays with less waste.

- Scalability: Can fabricate materials on a large scale, limited only by the size of the mold.

- Customization: Allows precise control over semiconductor structures through adjustments in mold dimensions, evaporation rates, and liquid composition.

Potential Applications

While the proof-of-concept demonstrated the creation of transistors and diodes, the possibilities extend much further. The ability to tune the bandgap of semiconductors and create photo-responsive structures opens doors to optoelectronics, sensors, and even advanced solar energy applications.

The inclusion of graphene sheets adds another layer of versatility, enabling innovations in fields like flexible electronics, energy storage, and medical diagnostics. “Looking to the future, I can imagine swarms of diffractive microbots performing super-resolution microscopy and other sensing tasks while walking across the surface of a sample,” said Julia Chang, a postdoctoral researcher and co-author of the study.

A Game-Changer for Electronics

“This technique represents a paradigm shift,” said Martin Thuo, a professor of materials science and engineering at NC State and the study’s corresponding author. “We’ve shown that self-assembling, highly structured, tunable electronic materials can be created for functional devices. The next step is developing more complex devices, such as three-dimensional chips.”

Future Implications

The simplicity and scalability of D-Met reactions could transform manufacturing in industries beyond electronics. For example, it might enable the development of efficient, flexible solar panels for aerospace or wearable technologies. Moreover, the process’s ability to integrate graphene with semiconductors hints at breakthroughs in quantum computing, nanotechnology, and energy storage.

The research, published in Materials Horizons, was supported by the National Science Foundation and conducted in collaboration with researchers from Iowa State University. With multiple patents pending, the D-Met technique is poised to disrupt the electronics landscape, making advanced manufacturing more accessible, efficient, and sustainable.