We created approximately 50 million tons of e-waste in 2018, a figure the UN referred to as a “tsunami of e-waste.”

While printed circuit boards, vital components of modern electronics, are only a fraction of the e-waste we create, once they’ve served their purpose, they are often burned or buried in landfills, polluting the air, soil and water. Most concerning are the brominated flame retardants added to printed circuit boards to keep them from catching fire. Now, researchers have developed a ball-milling method to break down these potentially harmful compounds, enabling safer disposal.

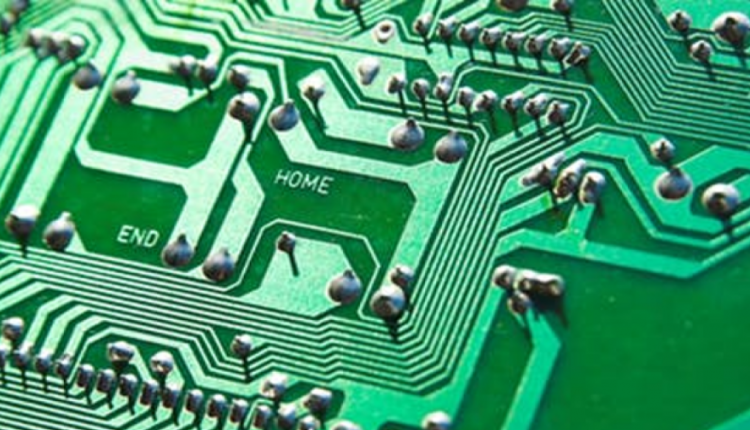

Composed of 30% metallic and 70% nonmetallic particles, printed circuit boards support and connect all of the electrical components of a device. Metallic components can be recovered from crushed circuit boards by magnetic and high-voltage electrostatic separations, leaving behind nonmetallic particles including resins, reinforcing materials, brominated flame retardants and other additives. Scientists have linked compounds in brominated flame retardants to endocrine disorders and fetal tissue damage. Therefore, Jujun Ruan and colleagues wanted to develop a method to remove the flame retardants from waste printed circuit boards so that they wouldn’t contaminate the environment.

The researchers crushed printed circuit boards and removed the metallic components by magnetic and high-voltage electrostatic separations, as is typically done. Then, they put the nonmetallic particles into a ball mill, a rotating machine that uses small agate balls to grind up materials. They also added iron powder, which prior studies had shown was helpful for removing halogens, such as bromine, from organic compounds. After ball-milling, the bromine content on the surface of the particles had decreased by 50%, and phenolic resin compounds had decomposed. The researchers determined that during the ball-milling process, iron transferred electrons to flame retardant compounds, causing carbon-bromine bonds to stretch and break.

The authors acknowledge funding from the 111 Project, the Natural Science Foundation of Guangdong Province, China and the Pearl River Star of Science and Technology.

Source: ACS