A Single Drop of Ethanol Upends Existing Nanosensor Manufacture

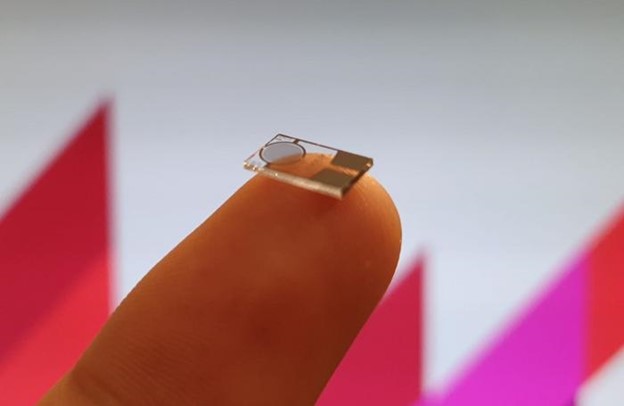

Macquarie University engineers invented a new technique to make the manufacture of nanosensors less carbon-intensive, much cheaper, more efficient, and more versatile. Treating each sensor with a single drop of ethanol replaces high-temperature heating materials. The research is published in the Journal of Advanced Functional Materials, titled, ‘Capillary-driven self-assembled microclusters for highly performing UV detectors.’

The nanosensor’s nanoparticles assemble into a network held together by weak natural bonds with many gaps between nanoparticles. Those gaps cause electrical signal transmission to fail. Most nanosensors don’t work effectively until heated. Heating, however, is a time-consuming and energy-intensive 12-hour process using high temperatures to fuse layers of nanoparticles, creating channels that allow electrons to pass through layers so the sensor will function.

There are downsides to this process, including the destruction of most polymer-based sensors, while nanosensors containing tiny electrodes can melt. The types of materials that can be used to make the sensors is limited because of the high heat used.

The new technique discovered by the Macquarie researchers entirely bypasses the heating, allowing nanosensors to be made from a much broader range of materials and eliminating the number of failures. Adding one droplet of ethanol onto the sensing layer helps atoms on the surface of the nanoparticles move around, and the gaps between nanoparticles disappear. The result is vastly improved efficiency and sensor responsiveness, surpassing the old method of heating for 12 hours.

How did they discover it? Postgraduate student Jayden (Xiaohu) Chen accidentally splashed ethanol onto a sensor while washing a crucible. He believed the sensor was destroyed, but the sample outperformed all other samples…he was onto something. The amount of ethanol, however, was anything but accidental, requiring painstaking work to come up with the right amount of ethanol to use.

The team has patents pending for the discovery, which has the potential to be very important in the nanosensor world.