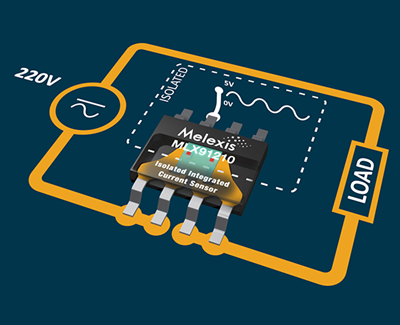

Melexis announced the MLX91210 family, expanding its portfolio of current sensing devices based on cutting-edge implementation of Hall effect technology. Running off a 5V supply, the MLX91210 ICs have current sensitivity levels down to 26.7mV/A and support linear current measurement ranges that span as far as ±75A corresponding to 30ARMS current.

Available in SO8 and SO16 package formats, these fully integrated Hall-effect current sensors have extremely low resistive losses (0.8mΩ for the SO8 and 0.7mΩ for the SO16) and provide high voltage isolation ratings (2.1 and 2.5kVRMS respectively), as well as accelerated responsiveness (within just 5µs). The sensor output of each IC is factory-calibrated for a specific current range and compensated for optimal stability in relation to temperature and over the course of its working lifespan, so that long term accuracy is maintained.

With provision to be factory calibrated for zero-current output point and sensitivity, each of these devices produces a linear analog output that is proportional to the current flowing directly through the IC’s leadframe. Inside the IC package, the magnetic field generated by the current flow is sensed differentially by two sets of Hall plates. This set up combats the effect of external fields and crosstalk. The close proximity of the Hall plates with the current conductor results in superior signal integrity, but at the same time a strong insulation layer separates the primary and secondary sides. The devices exhibit strong robustness against external fields, something that will get ever more critical as the density of power electronics designs increases. The key differentiator though is the virtually non-existent magnetic hysteresis that is witnessed, which results from the design not needing a ferromagnetic concentrator. A -40 to +125°C temperature range is supported, and the sensors comply with IEC-60950 (furthermore the SO16 packaged devices adhere to UL1577).

Thanks to their high speed and compact size, key applications for MLX91210 ICs that support both DC and AC current measurements, include precision current flow monitoring in power distribution units of server farms and data centres, power supplies and converters, demand response load control, household/appliance smart metering and energy intelligence, solar power converters and combiner boxes and electrical motor control in general.

Bruno Boury, Product Line Manager, Magnetic Sensing, Melexis, commented: “There is greater impetus for compact current/power monitoring in both domestic and industrial environments, with new legislative measures being established for higher efficiencies as well as financial concerns due to escalating energy costs. These new high speed devices are raising the bar in current sensor technology. Thanks to their compact form factors combining the sensing and isolation mechanism in a few tens of square millimetre footprint with very low ohmic losses, thermal drift compensation features and crosstalk immunity, they can be deployed into concentrated electronic systems and still deliver high degrees of accuracy.”

Comments are closed, but trackbacks and pingbacks are open.