An integrative approach to auto design and manufacturing systems

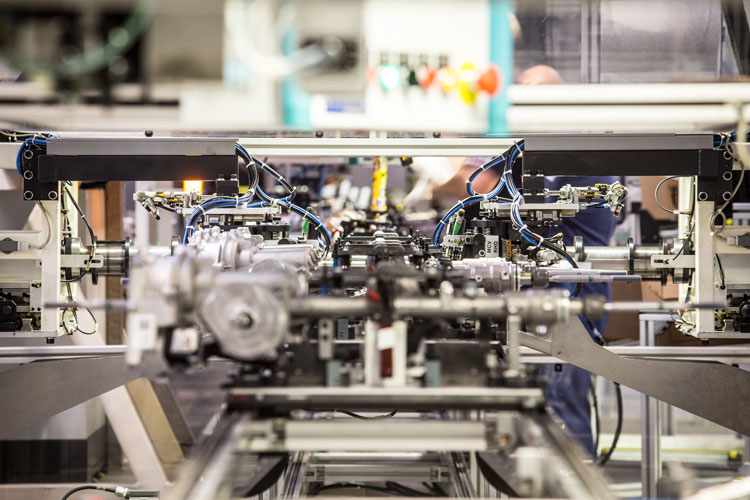

Nexteer Automotive has introduced Digital Trace Manufacturing, one of the most advanced, holistic, integrative approaches to design and manufacturing systems ever seen in the auto industry. The system uses the latest technologies and data analytics within one common, global architecture.

For customers, this will help deliver high-quality product performance while boosting value and global capacity optimization across all of Nexteer’s 24 manufacturing locations worldwide.

Nexteer is currently showcasing its industry-leading process automation systems during the 2018 North American International Auto Show in Detroit. Using virtual reality, guests can experience firsthand how Digital Trace Manufacturing integrates workstation optimization as part of a greater effort to improve processes.

“To enable Digital Trace Manufacturing, we’re using a connect-the-dots approach, in which the thousands of data-producing dots around the world are standardized and talk to one another. Each dot represents a machine, process, database, document, workplace robot and so on,” said Dennis Hoeg, vice president and North America chief operating officer.

“When the dots are connected, the result is one common, global architecture. Digital Trace Manufacturing allows Nexteer to deliver a dynamic, comprehensive view of its manufacturing operations in real time, which is a big payoff for our customers, employees and shareholders.”

Ultimately, Digital Trace Manufacturing gives Nexteer a more intimate understanding of its global operations at any given minute. Furthermore, any improvement in design or production made at one location can quickly be replicated globally.

Big data, industry trends and Nexteer’s unique approach

According to Hoeg, the difference between what Nexteer is doing and what is commonly referred to in the industry as “digital thread” or “manufacturing automation” is the vastness of what Digital Trace Manufacturing is covering. Because of the scope and the level of integration, it will take several phases to fully implement the entire system, Hoeg explained. However, he has already seen a positive impact on customer responsiveness and quality in the initial phases.

“The results are priceless as we implement future phases, and we expect the benefits to grow even more,” added Hoeg. “We are a technology leader, not only in what we do in advanced steering and driveline systems, but how we do it.”

Real-World Impact

- In implementing Digital Trace Manufacturing, Nexteer introduces several cutting-edge technologies and processes into its manufacturing operations. Ultimately, Digital Trace Manufacturing helps quality engineers proactively confirm product quality early in the process, potentially eliminating the need for costly end-of-line testing. Some examples include:

- Using a heat map to visually identify high-risk pallets in real time, allowing service personnel to proactively perform maintenance before an issue occurs

- Tracking and storing serial-number-specific data to measure performance along the manufacturing process

- Keeping a virtual ‘command center’ to analyze the root causes of rejected parts and make quick, corrective actions

- Integrating databases that capture product information so that complete analysis and swift problem-solving are possible

- Implementing a Manufacturing Execution System (MES), which monitors and manages processes in real time across factory floors

A System that Streamlines and Enhances Manufacturing Processes

Nexteer’s Digital Trace Manufacturing will connect all of the company’s manufacturing data points into one entity, enabling it to:

- Garner clear, real-time viewpoints of global manufacturing activities

- Predict future potential manufacturing issues and proactively solve issues before they become reality

Expedite and expand continuous improvements through a “smart” system that collects lessons learned and calibrates its decision-making accordingly - Accelerate design-to-production timelines via enhanced global collaboration across Nexteer’s regions and between manufacturing and product engineering divisions

- Optimize capacities, factory-floor logistics, inventory and planning

- Enhance component traceability for advanced quality control, tracking and reporting

- Streamline manufacturing employees’ environments with data-driven, ergonomic workstation design

- Access a virtual ‘command center’ for global manufacturing insights – anywhere, anytime – to improve decision-making and problem-solving

Nexteer recognized by Frost & Sullivan for manufacturing expertise

In recognition of its leadership in manufacturing excellence, Nexteer earned a Frost & Sullivan’s Manufacturing Leadership Award in 2017 in the Enterprise Technology Leadership category for its global implementation of advanced manufacturing and analysis technologies. These technologies streamline and interconnect product warehousing, traceability, quality management and other areas.

“Winners of the Manufacturing Leadership Awards have proven vision and innovation are alive and well in the manufacturing industry,” said David R. Brousell, global vice president, editorial director and co-founder of the Manufacturing Leadership Council.

“By embracing the technology-driven transformation we call Manufacturing 4.0, innovating new business models and leveraging engaged workforces, these leaders are laying the groundwork for a new era of greater productivity in manufacturing.”