Binding Polymers and Steel

Most new methods of developing materials created in the lab are not suited for industrial-scale use. Researchers at The Institute of Industrial Science at The University of Tokyo developed a cheap and straightforward method of bonding polymers to galvanized steel with a coating of zinc layered over it—to create a lightweight and durable material that companies can feasibly produce on an industrial scale.

Specifically considering the environmental impact of processes, new techniques are needed to ensure that parts can be made sustainably and have a long life. Galvanized steel is widely used in the automobile industry owing to its excellent mechanical properties and corrosion resistance. Polymer-metal composites are increasingly applied as alternative materials with high durability. Unfortunately, traditional bonding techniques of polymers to galvanized steel are unsuited for mass production.

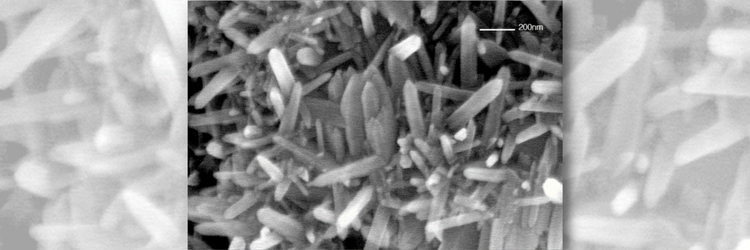

In a study published recently in the Journal of Manufacturing Processes, a team of researchers at The University of Tokyo demonstrated that a polymer can be bonded to galvanized steel simply by pre-treating the steel with an acid wash and dipping it in hot water. They discovered that when a polymer was applied to the treated metal, it filled in the tiny gaps and ridges between and within the needle structures, creating very strong mechanical linkages.

Tensile strength also increased with the complexity of the nanoscale structures on the galvanized steel surface.