Biomass Converted Into Clean-Burning Fuel

Twice a year, when the harvest is done on the millions of small farms in India, these farms go up in flames.

Satellite imagery of agricultural regions such as the Punjab shows thousands of smoke plumes rising as farmers burn biomass waste in the form of husks, stalks, and other plant residue in order to clear the land for another crop cycle. This smoke affects air quality locally and carries as far as major cities like Delhi. In fact, the practice of burning biomass in the open is so widespread that it was found to account for about 18% of global carbon dioxide emissions in a 2014 Stanford University study.

There is untapped value in this waste—especially as a biofuel alternative to coal. Once, farmers would have plowed it under as a type of fertilizer, returning nutrients to the soil. But today in India, synthetic and low-cost fertilizers, often subsidized by the government, have replaced these traditional methods.

What if there were a way to reduce the environmental burden of open burning and create a new revenue source for farmers, who often live near or below the poverty line?

Ahmed Ghoniem, the Ronald C. Crane (1972) Professor of Mechanical Engineering at MIT, and Kevin Kung, a PhD student in biological engineering and fellow in the MIT Tata Center for Technology and Design, are developing a technology that may help accomplish just that. Their project is a reactor that uses a process called torrefaction to densify biomass, making it transportable and increasing its shelf life. Torrefaction technology has been used at the industrial scale for more than a century, but it remains inaccessible to farmers in remote regions of the world. Ghoniem and Kung’s research seeks to make it a practical solution that could facilitate a meaningful income boost for smallholder farmers.

Cooking biomass

If biomass has value, and farmers have biomass, why are they burning it instead of selling it? Ghoniem and Kung have keyed in on transportation as the missing link.

Existing large torrefaction reactors “are not compatible with the distributed nature of biomass,” Ghoniem says. “Biomass is mostly available in rural, dispersed locations in small batches,” Kung adds. “It’s usually very bulky, loose, and wet. In remote areas, the waste is being burned because it doesn’t make sense to haul it to a processing center.”

If farmers could densify their biomass waste, this economic equation could change. Suddenly it might become an attractive proposition for biofuel producers to haul it away and add it to their energy feedstock. This cycle has the added benefit of helping meet the huge demand for affordable cooking and heating fuel in India and other developing countries.

That’s where the torrefaction reactor comes in.

“Torrefaction is good for long-distance transportation,” Kung says, “because for the same truckload you can carry a lot more units of energy, and people pay for the energy.”

So how does torrefaction work? Kung says it’s a thermochemical process a lot like cooking, and illustrates by explaining that he’s a “forgetful” chef.

“I put some food in the oven, and by the time I remember half an hour later, my food is charred. What has happened is similar to torrefaction, but we do it in a much more controlled manner,” he says.

In the torrefaction process, plant-based biomass containing carbon, hydrogen, and oxygen is heated to between 200 and 300°C in an oxygen-free environment. This treatment causes it to rapidly decompose, releasing low-energy molecules first.

“The first thing to come out of the biomass is water, so you are drying the biomass,” Kung says. “The next to come out is carbon dioxide, and then you start getting organic acids like ethanol and methanol. You end up with a solid fraction of biomass that’s much higher in carbon content. You are essentially converting it to something more like coal, with a much higher energy density.”

Another advantage of torrefaction is that it takes place in a closed, energy-efficient loop. The biomass releases combustible gases that are used to generate the required heat, making the process self-powering.

“Nothing blew up”

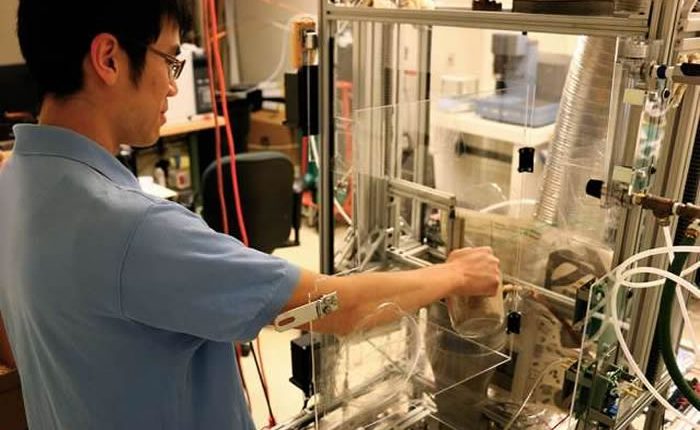

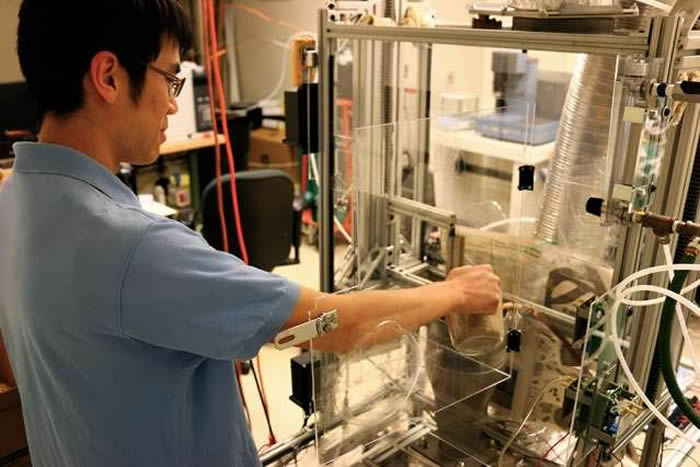

Ghoniem and Kung are wrapping up their lab-scale demonstration of the technology.

“We are working towards building an efficient small- to medium-sized reactor based on modeling the physics and chemistry of the process,” Ghoniem says.

One of the main challenges has been moving from a batch process, in which one lot of biomass is torrefied at a time, to a continuous process, in which biomass is fed through continually while conditions inside the reactor remain stable.

To be successful and economical on Indian farms, the reactor will have to be continuous, efficient, and mobile.

“Farmers have maybe one or two weeks after harvest before they feel compelled to burn the biomass and get ready for the next crop cycle,” Kung says. “There’s a short window in which this conversion has to take place. If it’s going to work in a decentralized area, the unit has to be able to move from farm to farm, doing the conversion on site.”

He says they are making progress toward the desired stability, avoiding calamitous failures so far: “We went from batch process to continuous process, and nothing blew up. In our first test it ran continuously for 45 minutes. I’m pretty happy about that.” Kung is no stranger to implementing technologies in the field: He previously started a biochar company in Kenya. But his PhD research aims to contribute to the fundamental scientific understanding of torrefaction as well.

“I hope to demonstrate that this is a continuous process reactor and to identify the optimal conditions for maximizing energy efficiency in this process,” he says.

Ultimately, they want to lay the scientific groundwork for deploying torrefaction in rural areas of developing countries. “We are starting with a lab-size system to optimize, and then we will scale it up,” says Ghoniem.

More information: Phys.org