Boosting Confidence in New Manufacturing Technologies

Additive manufacturing, including emerging “3D printing” technologies, is booming. Last year an astronaut on the International Space Station used a 3D printer to make a socket wrench in space, hinting at a future when digital code will replace the need to launch specialized tools into orbit. Here on Earth, the Navy is considering applications for additive manufacturing aboard ships, and a commercial aircraft engine company recently announced its first FAA-approved 3D-printed part. Despite its revolutionary promise, however, additive manufacturing is still in its infancy when it comes to understanding the impact of subtle differences in manufacturing methods on the properties and capabilities of resulting materials. Overcoming this shortcoming is necessary to enable reliable mass production of additively manufactured structures such as aircraft wings or other complex components of military systems, which must meet demanding specification requirements.

DARPA’s Open Manufacturing program seeks to solve this problem by building and demonstrating rapid qualification technologies that comprehensively capture, analyze and control variability in the manufacturing process to predict the properties of resulting products. Success could help unleash the potential time- and cost-saving benefits of advanced manufacturing methods for a broad range of defense and national security needs.

“The Open Manufacturing program is fundamentally about capturing and understanding the physics and process parameters of additive and other novel production concepts, so we can rapidly predict with high confidence how the finished part will perform,” said Mick Maher, program manager in DARPA’s Defense Sciences Office. “The reliability and run-to-run variability of new manufacturing techniques are always uncertain at first, and as a result we qualify these materials and processes using a blunt and repetitive ‘test and retest’ approach that is inevitably expensive and time-consuming, ultimately undermining incentives for innovation.”

The challenge with additively manufactured parts is that they are typically composed of countless micron-scale weld beads piled on top of each other. Even when well-known and trusted alloys are used, the additive process produces a material with a much different “microstructure,” endowing the manufactured part with different properties and behaviors than would be expected if the same part were made by conventional manufacturing. Moreover, parts made on different machines may be dissimilar enough from each other that current statistical qualification methods won’t work. Accordingly, each “new” material must be precisely understood—and the new process controlled—to ensure the required degree of confidence in the manufactured product.

To achieve this enhanced manufacturing control, Open Manufacturing is investigating rapid qualification technologies that could be applied not just to additive manufacturing but to any of a range of potentially new manufacturing methodologies. The program comprises three efforts—two focusing on metal additive processes and one on bonded composite structures:

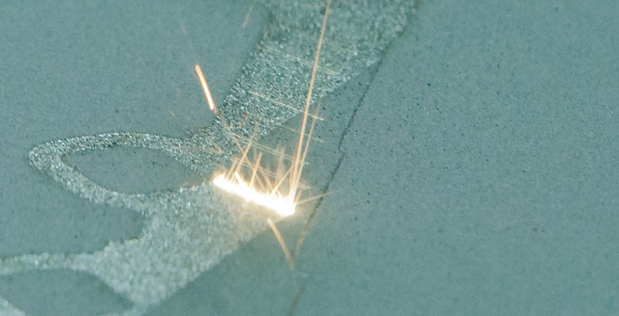

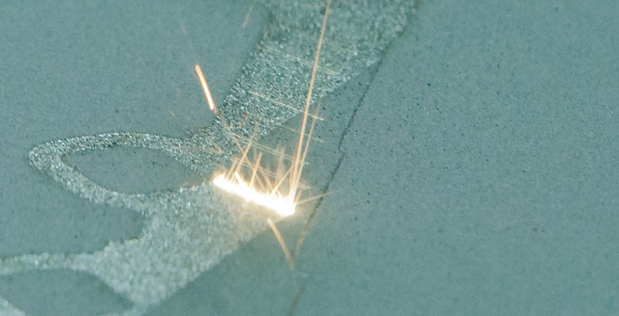

- The Rapid Low Cost Additive Manufacturing (RLCAM) effort aims to use first-principles and physics-based modeling to predict materials performance for direct metal laser sintering (DMLS) using a nickel-based super alloy powder. In DMLS a laser melts the metal powder to additively build a 3D product.

- The Titanium Fabrication (tiFAB) effort aims to combine physics- and data-based informatics models to determine key parameters that affect the quality of large manufactured structures, such as aircraft wings. tiFAB is a method that uses an electron beam instead of a laser to melt spool-fed titanium wire to build up a structure layer by layer.

- The Transition Reliable Unitized Structure (TRUST) effort aims to develop data informatics approaches for quantification of the composite bonding process to enable adhesives alone to join composite structures. State-of-the-art techniques rely on mechanical fasteners in addition to adhesives. TRUST seeks to eliminate the reliance on these fasteners, thereby enabling bonded composites to take advantage of adhesive joining to streamline assembly and lighten the weight of the structures. Open-Manufacturing also is developing several advanced manufacturing techniques to support defense needs. One of these, MicroFactory for MacroProducts, uses more than 1,000 microbots, each smaller than a penny, that zip around like small insects to efficiently assembly truss structures. Microbots have fabricated 12-inch truss structures with integrated electronics as a proof-of-concept, showing the potential for massive parallelism where thousands of microbots could simultaneously and efficiently build intricate truss structures. This technology could be applied to rapid production of advanced electronics for military systems or constructing wings for very small unmanned aerial systems, for example.Another concept being advanced is seamstress-less sewing, which could enable rapid production of U.S. military uniforms in the United States at lower cost. This demonstrated robotic system uses computer vision to accurately and quickly sew fabrics together with fine thread-count precision. Beyond its potential to support cost-efficient fabrication of U.S. military uniforms in the United States, this technology has the potential to boost the domestic apparel industry in general by, for example, enabling customized apparel production directly from a design.

- “Historically, U.S. military advantages were supplied by breakthroughs in materials and manufacturing,” Maher said. “More recently, the risks that come along with new manufacturing have caused a lack of confidence that has stifled adoption. Through the Open Manufacturing program, DARPA is empowering the advanced manufacturing community by providing the knowledge, control, and confidence to use new technology.”

- To support warfighters, the program is also demonstrating a framework for affordable, rapid manufacturing of customized orthoses, such as leg supports for injured veterans, in quantities of one. This effort would transform the current “artisan” approach for making customized orthoses—where each device is custom-crafted by a specialist—to an automated process allowing greater patient access, rapid device modifications and improved durability.

- The Open Manufacturing program has established two Manufacturing Demonstration Facilities (MDFs)—one at Penn State focused on additive manufacturing and the other at the Army Research Laboratory focused on bonded composites. The goal of these MDFs is to establish permanent reference repositories that endure long after the Open Manufacturing program concludes, where individuals can access various contributed approaches and processes models. The facilities also serve as testing centers to demonstrate applications of the technology being developed for the Department of Defense, its industrial base, and other agencies, and as a catalyst to accelerate adoption of the technology.