Car tires inspired by grasshopper feet could make driving safer

While bio-inspired robots are studied in excess these days, researchers are now looking into other bio-inspired technology, such as car tires.

A team of researchers from Lehigh University has teamed up with Michelin Corporation and the National Science Foundation to develop materials with surface architectures that could improve the safety and reliability of tires. Their work is inspired by surfaces on the feet of grasshoppers and frogs.

Anand Jagota, professor of chemical and biomolecular engineering and director of Lehigh’s bioengineering program, has spent his career focusing on how biomimetics could improve the adhesive and mechanical properties of rubbery materials.

His work appeared to well-known tire company Michelin years ago and the result is the current collaboration.

Jagota and his team have now revealed the new bio-inspired film-terminated structures with unique friction characteristics that could have positive industrial implications for, among other things, tires.

When it comes to tires, it’s usually impossible to improve traction, life-time, and fuel efficiency simultaneously. It seems that improving one aspect tends to degrade another.

“High quality tires minimize rolling resistance, which improves fuel efficiency, while maximizing the sliding friction that basically helps to brake quickly,” said Jagota. “To help increase this sliding friction, tires currently employ millimeter-scale structures to grip the road and channel water. We are working to create structures at the microscale that will enhance friction and adhesion control.”

The researchers turned to the smooth pad surfaces on the feet of grasshoppers or frogs. Previously, the team developed a thin film comprised of an array of tiny pillars on top of a substrate.

“We placed these pillars or posts in an hexagonal array and covered them with a thin coating that allowed them to make solid contact with rough surfaces and strongly enhances static friction,” said Jagota. “Dragging the film in any direction provided the same friction. But tires don’t require the same properties in all directions, so we went to an array of parallel ridges. We believed this would provide greater resistance to sideways movement across the film – and greater sliding friction.”

The team was fascinated by how well the ridges performed. The parallel ridges created a surface where the “good” lateral sliding friction was increased significantly.

“This was the most unexpected thing: in the ridge-channel geometry, the film improved sliding friction dramatically, by a factor of three or four,” said Jagota.

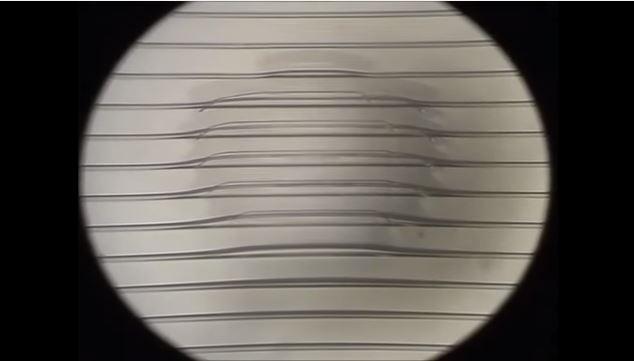

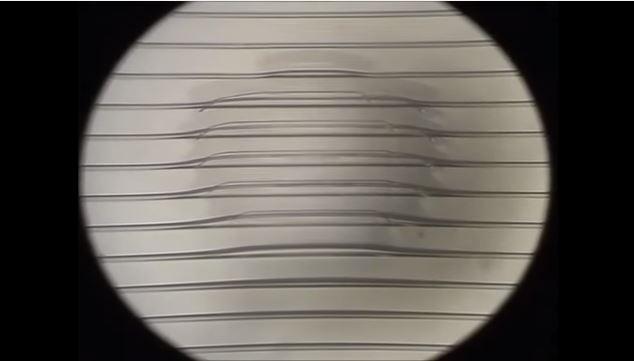

To test their ideas, the researchers created a film using rubber-like material which had rows of evenly spaced, parallel ridges, covered with a thin topcoat. With the film laid flat, a glass ball was pressed into the film and dragged across it in a direction perpendicular to the ridges.

They found that the increased sliding friction was a result of extreme contortion of the ridges. Under the pressure of the sphere, the ridges stretched and rode up on each other, creating broad areas of surface and internal contact. This internal sliding allowed unwanted energy to be released. The elastic energy that was absorbed during the contortion was then let loose as the ridges returned back to their normal form.

The team is optimistic about its results. Increased sliding friction could enhance a tire’s grip, as forward energy is released from the tire’s surface to dissipate as harmless heat and sound waves. With no commensurate increase in adhesion observed, rolling resistance should not be markedly increased.

While the work is still in its early stages, the collaboration is making it possible to place bio-inspired designed on the roads.

A video regarding the work can be seen below.

Story via Eurekalert.

Comments are closed, but trackbacks and pingbacks are open.