Although COVID-19 isn’t primarily spread by surface contact, the lack of testing and iyr failure, for the most part, to control its spread via social distancing, social isolation, and mask wearing has meant that since the pandemic began, people are focused on keeping their homes and workspaces squeaky clean to eliminate at least one source of potential infection. Hospitals and labs, especially, are meticulous, and this means added labor for already over-taxed health professionals.

Not every surface is easily reached. But a robot with an arm and six joints could make it possible, without a single human in the room.

Doctoral student Shantanu Thakar was among a team of USC Viterbi School of Engineering students and engineering professors that suggested that a robot they had developed a few years ago might be, with a few tweaks, up to the task.

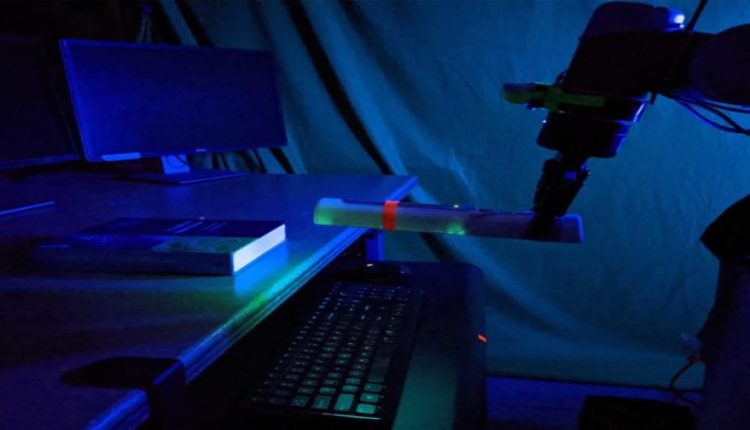

Named ADAMMS for “Agile Dexterous Autonomous Mobile Manipulation Systems,” the autonomous robot could open doors and pick up items to carry for people who would otherwise struggle to do so on their own. By adding an ultraviolet wand and robotic arm, the researchers found that the robot could also handle cleanup, sanitizing surfaces like a deep cupboard with (almost) a wave of the wand from its new arm with six joints.

The effort to design, manufacture and add ADDAMS’ new six-jointed arm grew from a handful of researchers to more than a dozen team members from across USC Viterbi, including master’s and PhD students from the Department of Aerospace and Mechanical Engineering and the Department of Computer Science. They also consulted UV light expert Andrea Armani, professor of chemical engineering and materials science. And the team members had to do it all while following social and physical distancing guidelines amid the pandemic.

Working with a few 3D printed parts and UV components, the team members held Zoom meetings to plan their steps and update each other on their progress. They also staggered their work schedules so they could observe social and physical distancing guidelines while gradually setting up ADDAMS with its new UV capabilities.

The USC Viterbi Center for Advanced Manufacturing housed the robot. Only three members of the entire team — doctoral candidate Sarah Al-Hussaini, master’s student Hyojeong Kim and postdoctoral candidate Pradeep Rajendran — visited it in person. They found that one person could man the robot while the other worked remotely from a different room in the building to direct the robot. The robot’s arm is fairly flexible.

Algorithms provide guide to robotic UV disinfection

The team engineered the robot so that algorithms guide its motion.

ADAMMS requires both a front-end and a back-end component, much like any computer. On the front end, a high-level directive like “clean this area,” is communicated. On the back end, algorithms developed by the researchers help the robot decide specifically which path to take to reach for an object and the exact scanning pattern used for disinfection.

“Once the robot is in the desired space, the robot arm will scan the space to get a sense of what it’s surrounded by,” said Kim, who worked on several individual modules which she integrated and implemented on the real robot.

The person controlling the robot will receive the scan as a 3D image, and then can click on a few objects to prompt the robot to plan a trajectory that would cover those objects and areas, and then sanitize them.

The UV light has to be directed at an object or area for a certain amount of time which factors in the light’s intensity and what the surface is made of.

UV light does not work on everything; for instance, fabrics or textured surfaces are better cleaned with disinfectants.

The robot, though, is incredibly customizable, so that it can clean different spaces. Changing the size of the mobile base or the robotic arm can improve its reach. Different types of grippers like a suction gripper — which could be 3-D printed on demand — can also help the robot manipulate objects and clean them.

UV disinfection: journey to deployment

For the ADAMMS robot to be effectively deployed to hospitals, offices and other critical spaces, first the user interface needs to be accessible through a diverse array of devices, like mobile phones and tablets, and made more user-friendly, Kim said.

In an ideal world, the team hopes the robot can be completely remotely operated — perhaps by a human in a different city or even country. “Someone sitting in the U.S. could disinfect a space in India or China, when it’s night there,” Thakar said. He also sees it as an opportunity to create jobs safely. “If we can easily and quickly train people to use this robot, people can remain in the safety of their homes while helping to make other spaces safe as well.”

Beyond the hospital, the researchers want to see the robot deployed for spaces like grocery stores, where disinfecting every nook and cranny is too labor-intensive for already overworked employees.

For surfaces that can’t be disinfected with UV light, the robot could be adjusted to carry a disinfectant that it would spray on surfaces.

“Since the robot is remotely operated, it’s well suited for stringent times like those we are now facing,” said Al-Hussaini.

Source: USC