These days companies are consistently coming up with ideas for your waste products. NASA is even converting human urine into drinking water for astronauts.

Here on Earth, a Washington-based company called Impact Bioenergy wants to use our food waste to create fertilizer and renewable fuels.

How it works

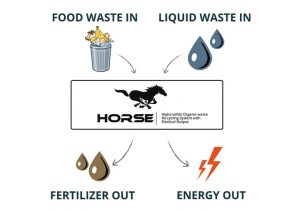

It works by putting old food into a giant machine called the HORSE (High-solids Organic-waste Recycling System with Electric output).

According to the company: “This is a living machine that eats food scraps and makes energy and plant food using microbes with zero waste. It’s portable. It’s affordable.

“It creates jobs and independence from fossil fuel energy and landfilling.”

The company’s vision is to eliminate trash-can garbage by turning it into renewable energy on your property.

As well as fertilizer for nearby gardens or farms to grow food and flowers.

The HORSE is another name for Impact Bioenergy’s Anerobic Digesting 25 Series Portable and Modular Bionergy System.

The capabilities

This is capable of consuming 25 tons of food scraps, beverages, fat, and paper products every year.

According to the company’s Kickstarter campaign, it has the potential to create 5,400 gallons of liquid fertilizer and up to 37MWh of raw energy every year.

While the company acknowledges that other methods such as composting are beneficial, many food wastes are just too wet and dense to compost easily.

By digesting the food wastes, conserving the nitrogen and water, and harvesting the energy, liquid fertilizer can be made by the HORSE.

The liquid can then be used to irrigate compost and make it even better.

“The digester biogas production and capture reduces greenhouse gas emissions and can be used as gas or used to make light, heat, electricity, or CNG vehicle fuel,” the company stated.

The HORSE

The HORSE works similarly to animals that acquire nutrients from plant-based food by fermenting it in a specialized stomach prior to digestion, like cows.

To acquire energy from the HORSE, the machine requires about three hours of work per week (loading feed, mixing the digester contents, checking readings, and drawing off the liquid as needed).

However, the company is already working on future automated designs that can reduce daily maintenance.

The HORSE systems can be delivered fully functional and ready-to-use and do not require any utility connections.

A HORSE can even be delivered on a trailer to use the waste from events and festivals.

The system comes with a 12V back-up system that heats and manages biogas production without the need for auxiliary power.

According to Impact Bioenergy’s website: “We understand that communities and organizations are seeking more sustainable and affordable sources of energy and methods of waste diversion.

“The best solutions are located at the source, yielding the greatest economic and environmental impact. Our systems are ideally suited to small to mid-size communities, campuses, and commercial generators of organic waste.

“The 25 series offers continuous distributed, off-grid energy, reducing reliance on power transmission across the landscape, and providing energy independence and security.”

Pricing

The cost of producing one HORSE is about $43,000.

Therefore, the company has launched a Kickstarter campaign to get folks on-board.

To learn more or support the cause, visit the company’s Kickstarter campaign.