Device Tests Friction, Wear Associated with EV Fluids

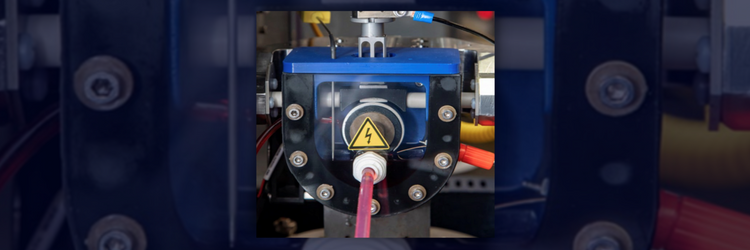

A Southwest Research Institute team created a mechanical testing device that analyzes fluids and lubricants formulated for electric vehicles. The team modified a commercial tribology testing device, enabling it to evaluate the impact of electric currents in fluids, measuring the wear and friction on the automobile parts in the presence of an applied voltage.

The Tribology Research and Evaluations section at SwRI designed a new test apparatus modeling the effects of electrification on rotating parts. Most EVs use alternating current (AC) induction or permanent magnet motors powered by onboard battery packs. An inverter takes the direct current voltage input from the batteries and converts it to AC power to operate a vehicle’s engine.

The DC-to-AC frequency conversion speed can cause local voltage spikes requiring grounding. Motor bearings are susceptible to electric currents flowing due to their location near voltage spikes. Electric potential for the bearings builds until the voltage becomes strong enough to break down the thin lubricant film causing surface damage and scarring.

The team tested several commercial lubricants, measuring wear scarring and friction on the bearing raceways and bearing shells, and found that electric potential across a fluid can affect wear and bearings friction by as much as 20%.