Shape-memory metals that revert from one shape to another by being warmed or otherwise triggered are valuable as actuators that control the movement of various devices. A new category of shape-memory materials made of ceramic rather than metal has potential in high-temperature settings, such as actuators inside a jet engine or a deep borehole. Researchers will report the new findings in the journal Nature.

Shape-memory metals have long been used as simple actuators but are limited by the achievable service temperatures of the metals used—at most, a few hundred degrees Celsius. Ceramics can withstand much higher temperatures, sometimes up to thousands of degrees, but are brittle. An MIT team has found a way to overcome that and produce a ceramic material that can actuate without accumulating damage, functioning reliably as a shape-memory material through many use cycles.

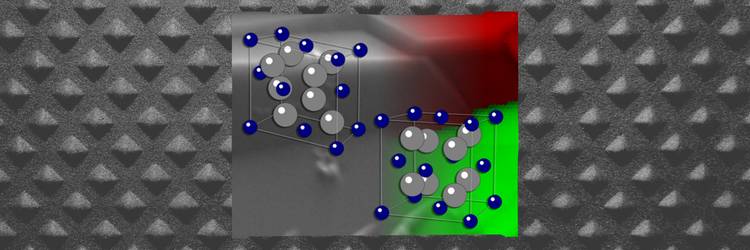

The team succeeded with a new variation of zirconia. Atoms of different elements were introduced into its structure in a way that altered some of its properties. These elements dissolve into the lattice, sculpt it, and change that transformation; they make it more gentle at the atomic scale.

One common application of shape-memory materials is relief valves. If a tank of something exceeds a specific critical temperature, the valve is triggered by that heat, automatically opening to relieve pressure and prevent an explosion. Actuators that direct airflow inside a jet engine might be a useful application.

The team plans to continue exploring the material, finding ways to produce it in bigger batches and more complex shapes, and testing its ability to withstand many cycles of transformation.