Engineers Develop Stretchy Optical Sensors To Make Robotic Hands More Efficient

Industrial robots are capable of achieving extremely precise control and manipulation with very few sensors, but now roboticists at Carnegie Mellon University are working to develop soft robots that can interact routinely and safely with humans by focusing on tactile and force sensing.

The CMU researchers have developed a robotic hand with three fingers and then figured out how to get it to be more nimble by embedding multiple fiber optic sensors.

The team turned to fiber optics to place 14 strain sensors into each of the fingers in the robotic hand, which gave it the ability to determine where its fingertips were and even to detect forces of less than a tenth of a newton. The material used to create the stretchable optical sensor, could potentially by used to further develop robotic skin so that it is capable of providing more feedback.

“If you want robots to work autonomously and to react safely to unexpected forces in everyday environments, you need robotic hands that have more sensors than is typical today,” said Yong-Lae Park, assistant professor of robotics, in a news release. “Human skin contains thousands of tactile sensory units only in the fingertip and a spider has hundreds of mechanoreceptors on each leg, but even a state-of-the-art humanoid such as NASA’s Robonaut has only 42 sensors in its hand and wrist.”

The team decided on the fiber optic method as opposed to adding conventional pressure or force sensors since those sensors can create complicated wiring systems that can easily break and catch interference from electric motors and other electromagnetic devices. Optical fibers simplify the process since one optical fiber can contain several sensors. In this study, all of the sensors in each of the fingers of the CMU hand are connected with four fibers. Optical sensors are not prone to electromagnetic interference either.

To create the robotic hand that mimics the bone structure of humans, mechanical engineering students, Leo Jiang and Kevin Low, 3-D-printed the bones out of hard plastic and incorporated eight sensors for detecting force. Each of the three sections of the hand was covered with a soft silicone rubber skin embedded with a total of six sensors that detect where contact has been made. A single active tendon works to bend the finger, while a passive elastic tendon provides opposing force to straighten the finger.

The duo incorporated commercially available fiber Bragg grating (FBG) sensors which detect strain by measuring shifts in the wavelength of light reflected by the optical fiber.

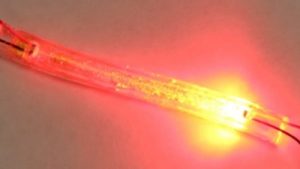

While optical sensors have many advantages in the field, Park decided to make them even more efficient by making them stretch and using a combination of commercially available silicone rubbers. These soft waveguides are lined with reflective gold so that as the silicone is stretched, cracks develop in the reflective layer and allow light to escape. By measuring the loss of light, the researchers are able to calculate strain or other deformations.

According to the CMU team, this kind of flexible optical sensor could be incorporated into soft skins that would not only be able to detect contact, but also measure force.

For more information, view the full news release.