Engineers Discover How To 3D Print Soft And Agile Octopus-Like Tentacles

While 3D printing has opened the doors to many opportunities, until now, 3D printing methods could not directly print a soft robotic device with much agility and degree of freedom. Until now.

Cornell University engineers have developed a method to re-create the arrangement of muscles of an octopus tentacle, using an elastomer and 3D printer.

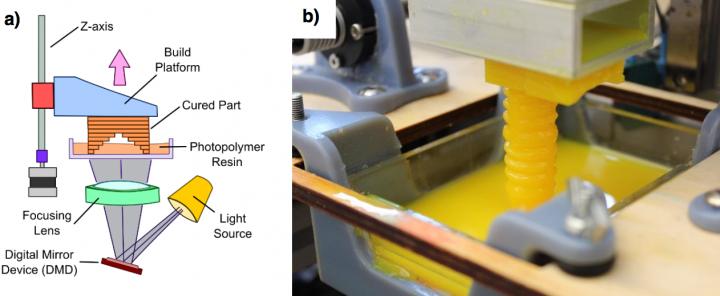

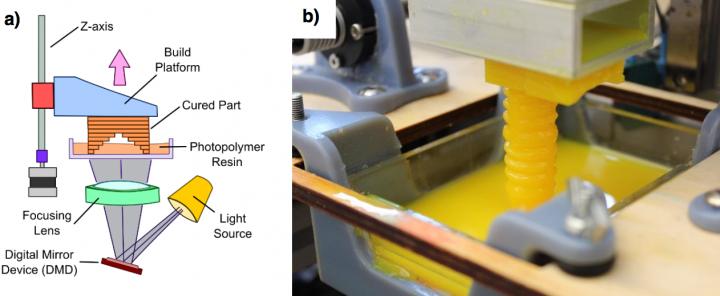

Rob Shepherd, assistant professor of mechanical and aerospace engineering and senior author of the study, and his team developed the mechanical design using a digital mask projection stereolithgraphy system for the 3D printing of soft actuators.

The system is detailed in a recent study published in the journal Bioinspiration & Biomimetics, by Ph.D. student and lead-author Bryan Peele and the team of researchers.

“Based on the demonstration reported here and the possibilities for improved materials, this nascent printing process for soft actuators is a promising route to sophisticated, biomimetic systems.”

Watch the video here.