How do you get lithium ion batteries to last longer and operate faster? According to scientists from Lawrence Livermore National Laboratory, by treating them with hydrogen.

High performance lithium ion batteries, rechargeable batteries that move lithium ions from the negative electrode to the positive electrode during discharge and back when charging, are in growing demand.

Key characteristics of lithium ion battery performance include capacity, voltage and energy density and are determined by the binding between lithium ions and the electrode material. Subtle changes in the structure, chemistry and shape of an electrode will affect how strongly lithium ions bond to it.

The Livermore team discovered that hydrogen-treated graphene nanofoam electrodes in the batteries show higher capacity and faster transport.

“These findings provide qualitative insights in helping the design of graphene-based materials for high-power electrodes,” said Morris Wang, an LLNL materials scientist who co-authored the research paper.

Lithium ion batteries are also becoming popular choices for electric vehicles and aerospace applications. Instead of heavy lead plates and acid electrolytes, companies are opting to use lightweight lithium ion battery packs that can provide the same voltage as lead-acid batteries without requiring modification of the vehicle’s drive system.

Commercial applications of graphene materials for energy storage devices, including lithium ion batteries and supercapacitors, depend on the ability to produce these materials in large quantities and at low cost. However, the chemical synthesis methods frequently used leave behind significant amounts of atomic hydrogen and the effect of the atomic hydrogen on the electrochemical performance of graphene derivatives is difficult to determine.

The LLNL team revealed that hydrogen to treat defect-rich graphene can actually improve rate capacity because hydrogen interacts with the defects in the graphene and opens small gaps to facilitate easier lithium penetration, in effect improving transport.

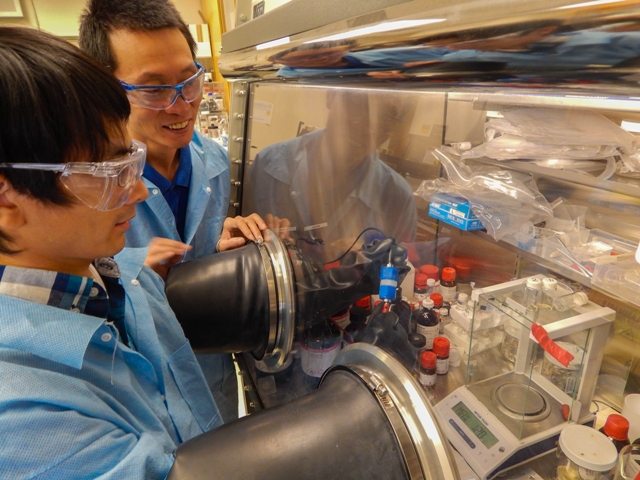

“The performance improvement we’ve seen in the electrodes is a breakthrough that has real world applications,” said Jianchao Ye, who is a postdoc staff scientist at the Lab’s Materials Science Division, and the leading author of the paper.

To study the storage capabilities of the batteries, the team applied various heat treatment conditions combined with hydrogen exposure and looked into the electrochemical performance of 3D graphene nanofoam (GNF) electrodes (made of defective graphene).The team opted to use 3D graphene nanofoams because they have so many applicationg including hydrogen storage, catalysis, filtration, insulation, energy sorbents, capacitive desalination, supercapacitors and lithium ion batteries.

The binder-free nature of graphene 3D foam makes them ideal for mechanistic studies without the complications caused by additives.

“We found a drastically improved rate capacity in graphene nanofoam electrodes after hydrogen treatment. By combining the experimental results with detailed simulations, we were able to trace the improvements to subtle interactions between defects and dissociated hydrogen. This results in some small changes to the graphene chemistry and morphology that turn out to have a surprisingly huge effect on performance,” said LLNL scientist Brandon Wood, who directed the theory effort on the paper.

What the research suggests is that controlled hydrogen treatment may be used as a strategy for even better lithium transport and reversible storage in other graphene-based anode materials.

Story via Lawrence Livermore National Laboratory.

Comments are closed, but trackbacks and pingbacks are open.