Industry 4.0: Man and machine – a time old dichotomy

Man and machine – a time old dichotomy: but as machines evolve, is it only a matter of time before humans are surpassed and become as redundant as a factory worker in the Changying Precision Technology Company factory in Dongguan? (The company replaced 90% of its workers with robots).

The traditional factory environment has been digitally transformed creating Industry 4.0. Though this transformation isn’t simply a swap of metal over man on assembly lines. The Industrial Internet of Things (IIoT), has introduced machine intelligence and cloud computing to create a smart ecosystem, leading to companies such as Ferrari embracing IIoT technologies within its factory.

Companies such as Alibaba Cloud are examining how to make better use of the data collected from the IIoT. Thousands of terabits of data are collected from the factory line, but the users only look at errors. Alibaba Cloud use Artificial Intelligence (AI) to analyze all of this data to optimize the yield rate. For example, Alibaba Cloud did this in China to help the largest solar panel provider save $1m per year.

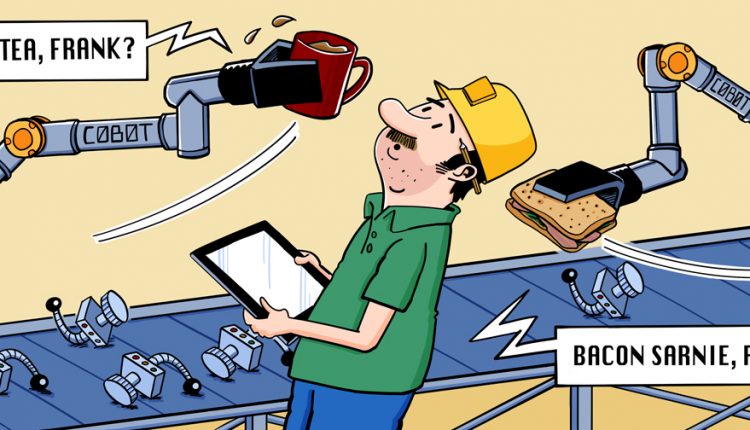

Then there are the cobots. The global collaborative robot (cobot) market is projected to grow from $175.500m in 2016, to $3,811.483m by 2021. Although here, Nigel Smith, CEO of TM Robotics, explains why manufacturers really need to understand the facts before they jump on the cobot bandwagon, as this investment may not be as low-risk as it first appears. Stewart Robinson, Principal Engineer and Functional Safety Expert at TÜV SÜD Product Service, also looks here at the safety implications as robots work ever-closer with humans, and become cobots.