Jaguar Has Recycled 50,000 Tons Of Aluminum To Create New Cars

Over the past year, automaker Jaguar has been recycling aluminum — 50,000 tons of it — as part of its project REALCAR (REcycled ALuminium CAR).

To give you an idea of how much aluminum that it is, 50,000 tons is about the weight of 200,000 Jaguar XE body shells. Their efforts have prevented more than 500,000 tonnes of CO2 equivalent from entering the atmosphere by not using primary aluminium material.

Project REALCAR involves 11 UK press shops that implement a closed-loop, segregating waste aluminium scrap so that it can be sent back into production to be re-melted into recycled aluminium sheet for use in Jaguar Land Rover vehicles.

Recovering aluminium in this way offers sustainability benefits, with aluminium recycling requiring up to 95% less energy than primary aluminium production.

“Innovation is at the heart of everything we do at Jaguar Land Rover. We are driven by the desire to produce increasingly world-class, light-weight, vehicles, but we also want to be world leading in how we build them,” Nick Rogers, Group Engineering Director.

The structural grade of recycled aluminium has since been tested and introduced in the aluminium bodies of the All-New Jaguar XF and F-PACE models.

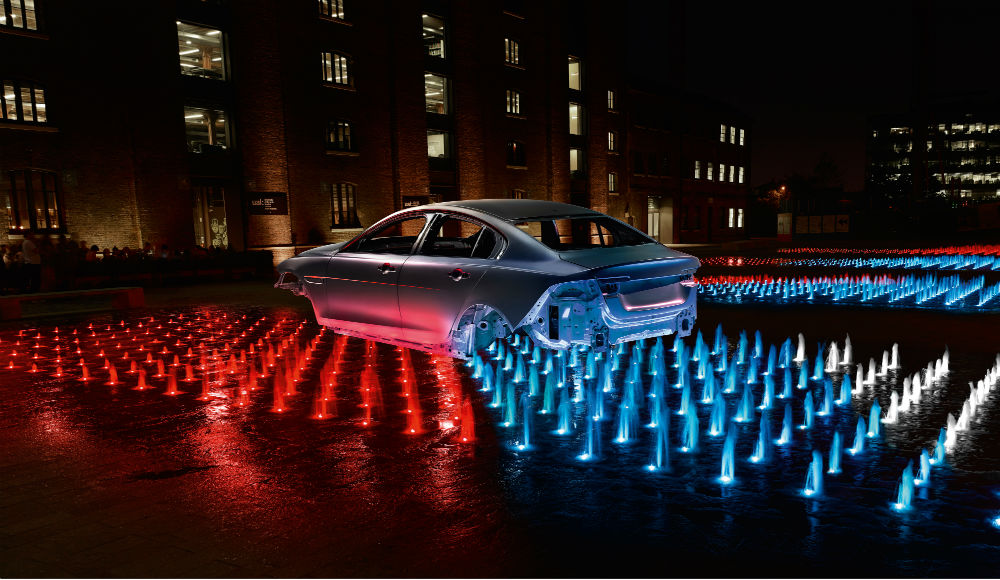

Take a look behind the scenes of the project.

Comments are closed, but trackbacks and pingbacks are open.