DoE’s Oak Ridge National Laboratory have scientists developed a scalable, low-cost method to improve the joining of materials in solid-state batteries solving the main challenges of safe, lasting energy storage systems.

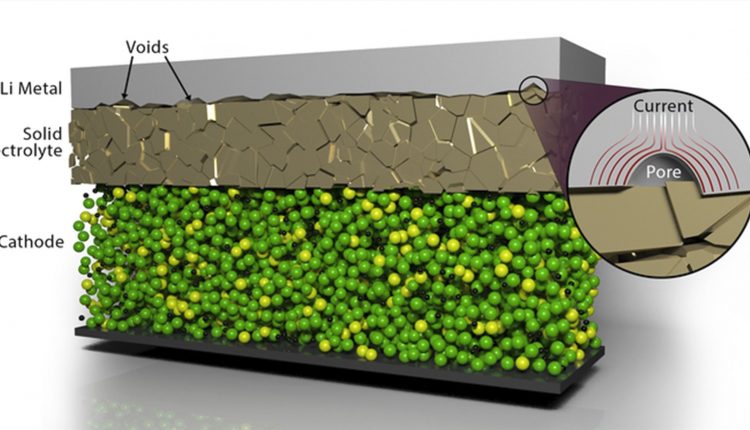

Solid-state commercial battery systems have the potential to provide 2x the energy density of lithium-ion batteries in a smaller footprint. The problem, however, is having materials join and remain stable during constant charging and discharging, called contact impedance. Processes to date have not worked.

The pulse that the researchers used eliminates the voids that form when joining layers of lithium metal anode material with a solid electrolyte material. Applying short, high-voltage pulses led to increased contact at the interface of the materials with no detrimental effects, as published in ACS Energy Letters.

The new method results in a local heat-generating current surround the lithium metal-encased voids, causing them to dissipate. The promising research is ongoing and includes experiments with more advanced materials and scaling the breakthrough to create a working-scale solid-state battery system.

Original Release: Eureka Alert