Patients who need to wear prosthetic devices encounter a series of issues while doing so. For example, the joint sockets don’t always fit correctly and patients can suffer from a variety of rashes and cysts. Thes issues are a result of the pressure that the prosthetic devices place on the soft tissue of their bodies.

Researchers at Tel Aviv University, FOM Institute AMOLF and Leiden University in the Netherlands have come up with a new way to manufacture mechanical “metamaterials,” the synthetic composite materials not usually found in natural materials, that are programmed to deform in a complex way.

These new findings could impact the future of soft robotics and wearable technologies, leading to more close-fitting, comfortable and user-friendly prostheses.

“We started with a series of flexible building blocks, or bricks, that had deformation properties that varied with their position,” said Dr. Yair Shokef of TAU’s School of Mechanical Engineering. “The blocks were able to change their shape when we applied pressure. From there, we were able to develop a new design principle to enable these bricks to be oriented and assembled into a larger metamaterial with machine-like functionalities.”

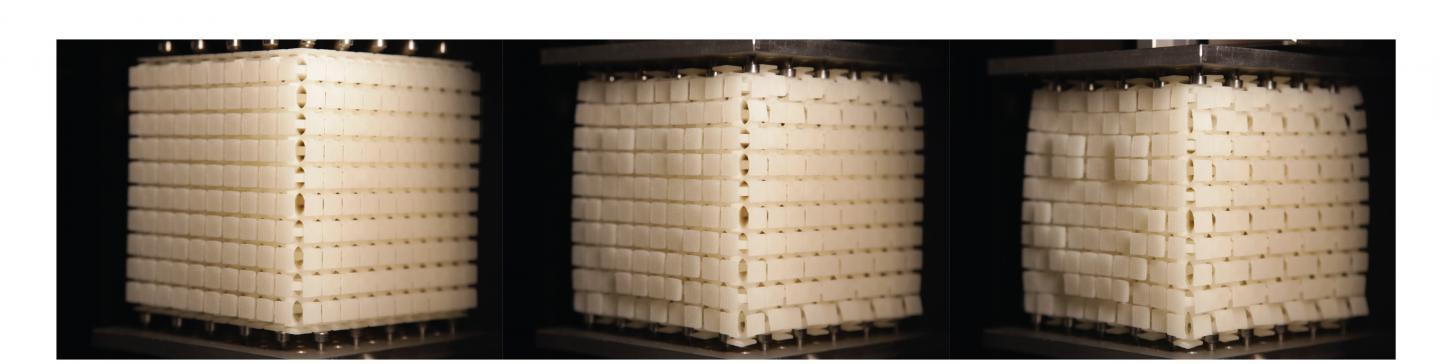

The metamaterial has the unusual property that spatially-patterned compression in one direction leads to predictable spatially-patterned deformation— like dents and protrusions — in other directions.

“Using metamaterials, we can program the material’s behavior by carefully designing its spatial structure,” said Shokef.

“For example, a pattern of holes in a sheet of material produces a mechanical response that is completely different than in the same material without holes,” said and Prof. Martin van Hecke of Leiden University. “We also wanted to investigate this phenomenon for a three-dimensional pattern of holes.”

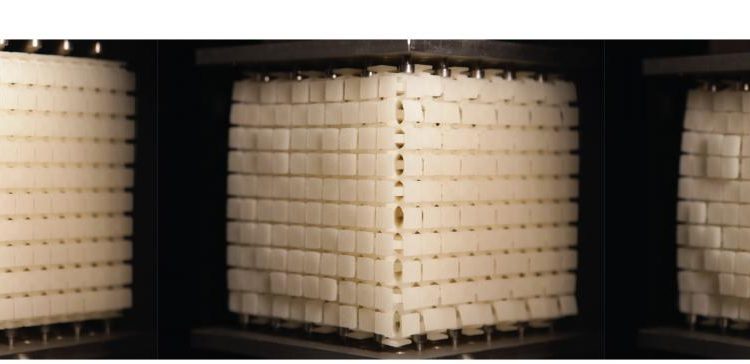

The researchers determined all the different stack possibility outcomes for the different cube building blocks and then developed a cube of 10 x 10 x 10 centimeter blocks on which a smiley face appears when the cube is compressed. This proved that any given pattern can be produced on a cube’s surface.

“For each possible stack, the deformation within the cube results in a specific pattern on the sides of the cube,” said Shokef. “We can carefully combine the building blocks in a way that any desired pattern can appear on the sides of a compressed cube. We can also use the cube to analyze these patterns.”

According to the researchers, a programmable machine material would be ideal for prostheses, or any other wearable in which a close fit with the body is necessary. And if they can determine how to make the blocks even more complex or from different materials, they say the “possibilities are really endless.”

Watch the video for more information.

Comments are closed, but trackbacks and pingbacks are open.