MIT’s MultiFab 3D Printer Can Print 10 Different Materials At Once

Now that there are plenty of 3D printers available on the market, researchers from MIT’s Computer Science and Artificial Intelligence Lab have decided to tackle a new challenge: how to print different materials from the same 3D printer.

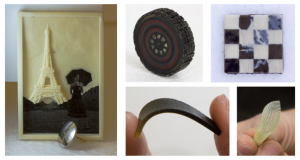

And they say they’ve figured it out by creating a new 3D printer that’s “better, cheaper, and more user-friendly,” and uses 3D-scanning techniques to print 10 different materials at the same time.

The “MultiFab” printer, which cost the team about $7,000 in off-the-shelf parts to create, can self-calibrate and self-correct, freeing users of that responsibility. The printer also lets users embed components like circuits and sensors, into their creations which means that once the product is printed it would be totally complete — “moving parts and all, in one fell swoop,” according to MIT.

“The platform opens up new possibilities for manufacturing, giving researchers and hobbyists alike the power to create objects that have previously been difficult or even impossible to print,” says Javier Ramos, a research engineer at CSAIL, said in an MIT news release.

So far, the CSAIL team has used the MultiFab printer to create a variety of objects such as smartphone cases and LED lenses and envision their printer will be useful for applications in consumer electronics, microsensing, and medical imaging.

“Picture someone who sells electric wine openers, but doesn’t have $7,000 to buy a printer like this. In the future, they could walk into a FedEx with a design and print out batches of their finished product at a reasonable price. For me, a practical use like that would be the ultimate dream,” said Ramos.

Next they will try to embed motors and actuators into their creations in an attempt to 3D print a functional robot.

For a more in-depth look at the printer watch the video below.

Learn more at MIT.