The researchers over at MIT’s Tangible Media Lab have been working to develop thin-film shape-changing surfaces.

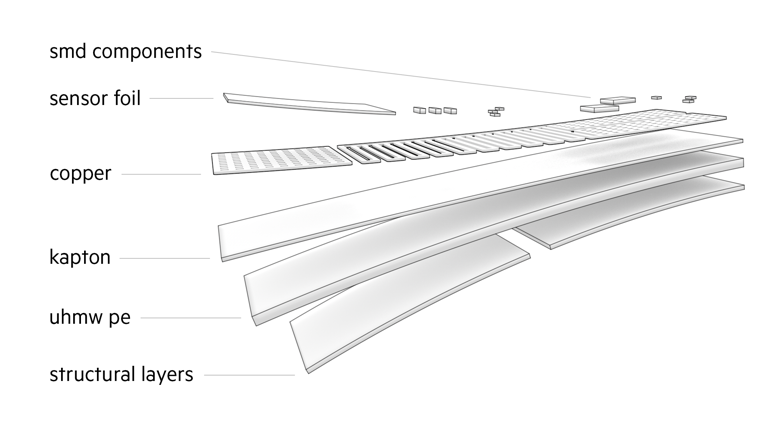

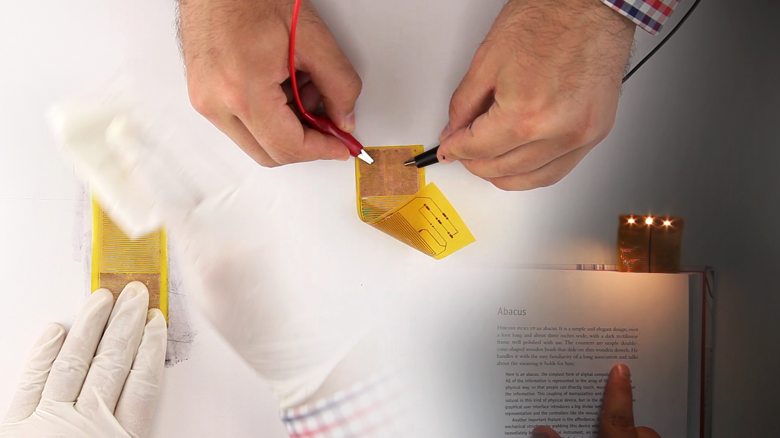

The team, Felix Heibeck, Basheer Tome, Clark Della Silva, and Hiroshi Ishii, was able to combine the thermoelectric characteristics of copper with the high thermal expansion rate of ultra-high molecular weight polyethylene in order to actuate the shape of flexible circuit composites.

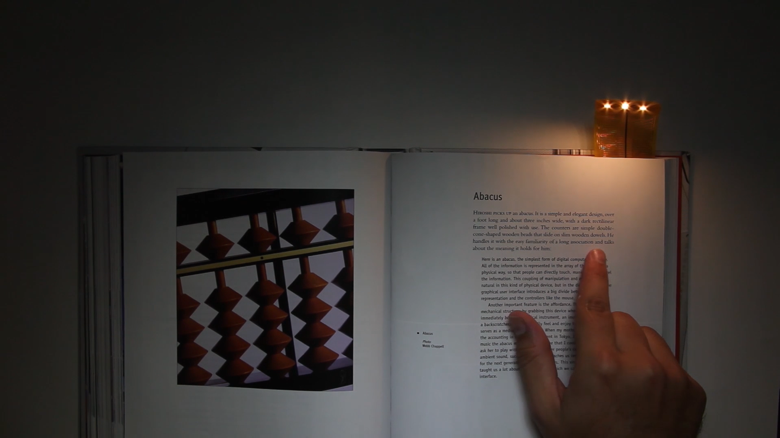

The uniMorph technology has potential to enable rapid digital fabrication and customization. The shape-changing is enabled by a temperature driven mechanism and reduces the complexity of fabrication for thin shape-changing interfaces.

UniMorph composites can be manipulated by either environmental temperature changes or active heating of embedded structures and can morph in different ways. The team also discovered that they could embed varieties of sensors that would leverage the existing copper structures.

Watch the team’s video to learn more about the uniMorph technology.

Comments are closed, but trackbacks and pingbacks are open.