Smaller size has always been a goal of virtually any manufactured good. From a material standpoint, smaller means fewer materials and lower cost. From a user’s perspective, smaller means easier to carry, fit in a pocket, and transport. From an environmental standpoint, smaller means less landfill waste and less recycling materials.

As engineers, we have seen semiconductors shrink in size, density, and complexity. Our modern-day devices could not exist or function today if we still used large geometry fabrication techniques. Because of advancements in higher-density lithography techniques and finer-resolution deposition technologies, we fit more functionality in smaller areas (and volumes) of silicon. So far, the Apple ARM-based dual die M1 ultra system on a chip fabricated using TSMC’s 5 nm process holds the record with 114 billion transistors on a single chip.

Understandably, smaller manufacturing capabilities often lead to superiority regarding battlefield gear. More highly effective, lighter, weight body armor, for example, lets soldiers expend less energy while maintaining protection from enemy fire. Lighter weapons and ammo mean more can be carried. And more delicate, more effective medications (and medical devices) save the lives of wounded soldiers.

And make no bones about it, micromanufacturing ability is a source of pride for companies, military equipment makers, and governments. So much so that when a Soviet assassin used micro-machined spheres filled with ricin to assassinate a journalist using an umbrella point injection mechanism, the west was shocked to see the prowess of the soviet micro-manufacturing and machining capabilities. There was a micromachining size gap.

Since then, AT&T Labs’ earliest abilities to perform ‘molecular clustering,’; the ability to manipulate individual molecules, to IBM’s ability to spell IBM using individual Xenon atoms on a substrate, has been indicative of our need to machine things on a molecular level. And we have done it.

So, we can now manufacture nanoparticles and nano technologies effectively and reliably. To be clear and for common understanding, nanoscience typically refers to things between 1 and 100 nanometers. And like every other advance, it has the potential for the greater good or worsened evil.

Most people don’t know that nanotechnologies and products are around us now and being used more and more ubiquitously. For years, nanoparticles have been added to sunscreen to make the sunscreen more effective.

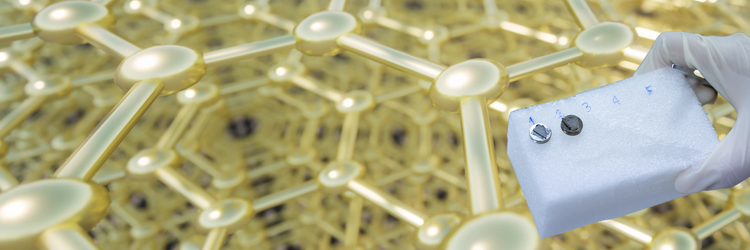

Graphene, an allotrope of hexagonally arranged single layers of carbon atoms, is lightweight, strong, and can act like a near-room-temperature superconductor. It can be layered and stacked as a honeycombed building block to create carbon nanotubes. This technology, combined with Kevlar, is the next form of carbon nanotube body armor. There is more. Doped with impurities between layers, graphene creates a range of new electro-physical effects. It is thermally conductive, stronger than steel, and, most importantly, nontoxic to biological organisms.

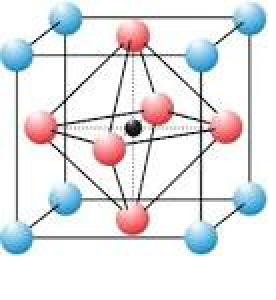

Another practical nano-structured material is perovskite. Perovskite is a crystalline structure that can be considered a dual tetrahedron inside a cube. While discovered in the form of calcium titanium oxide, other atoms can be used to create a structurally solid and stable crystalline lattice that can exhibit unique electrical properties. The centers and corners can maintain a positive charge, while the faces can carry a negative charge.

The crystals can exhibit colossal magnetoresistance like ferroelectric materials. Their electrical resistance changes in the presence of a magnetic field. Or, they can have no resistance at all. Through charger ordering, perovskite can be used as a spin-limiting transport. Imagine it as rectifying orbital spins. This has enormous potential for quantum computing and quantum electronics. In addition, perovskite-based solar cells hold the record for solar efficiency in solar panels. Perovskite also holds promise for fuel cells and fusion reactor materials.

Nanoparticles can also be combined to create nanorobots. These are already being used to perform base editing of specific chromosome genes. This could eliminate incorrectly coded genetic sequences and cure genetic diseases. Modern-day research is homing in on the reliable creation of reciprocates, or artificial red blood cells. Research is also yielding exciting results for nanorobotic microbivores, machines that eat microbes. Nanorobotics are also aiming for Clottocytes or robotic clotting agents.

Perhaps the most widespread use of nanotechnology is in the use of the mRNA Covid vaccines. Lipid nanoparticles are used to deliver the mRNA through the cell membrane and into the cell.

If past behavior and performance can predict future events, the industry will rush profit-making inventions to market before they are entirely safety tested. Disposing of nanoparticles needs to be addressed. Many of these particle sizes and types do not occur in nature. Many can be toxic to living organisms. Many could be weaponized and used with terrible consequences.

And many may invisibly find their way into deodorants, air fresheners, detergents, and other household items we use regularly. Let’s not run boldly into the darkness. Let’s make sure what we are creating is safe and sustainable.