Nanostructure research leads to high strength energy applications

Scientists use a liquid metal technique to selectively remove elements from a block of well-mixed metals and create intricate structures; as liquid metals can be fairly good atom thieves. However, researchers didn’t know how the technique worked. Now, scientists have found that due to the preferential mixing of the soon-to-be-removed element with the liquid metal, the uniform solid alloy is transformed into two phases in a manner that is similar to what is seen in cooling a hot mixture of oil and water.

Then, depending on the initial composition of the alloy and diffusion, the liquid metal can infiltrate the alloy resulting in two interpenetrating connected phases, leading to metal nanostructures with desirable properties.

The results of this work could lead to the ability to design materials that have extensive surface areas that can be used in batteries as high durability silicon electrodes. This work could also lead to radiation-tolerant materials for potential use in nuclear power generation.

Some liquid metals have been observed to transform uniform solid alloys into complex structures–a process that is not well understood. In this research, the process was found to begin with the liquid metal preferentially mixing with one of the elements in the multi-element solid alloy.

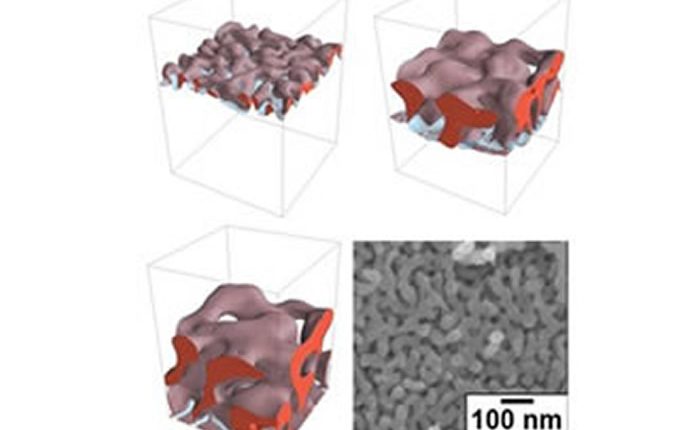

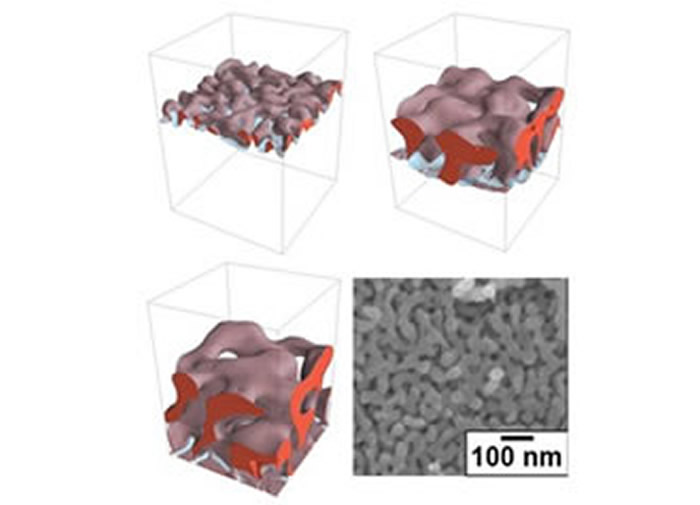

This creates two separate phases. Upon freezing, a two-phase nanocomposite forms. This process was studied, with both modeling and experimentation, for a single-phase tantalum-titanium alloy that was dealloyed by a copper liquid metal.

There is excellent agreement between the simulated and experimentally observed microstructures. Simulations further reveal insights on how the elements in the alloy behaved when in contact with the liquid metal.

The preferential interactions of the elements in the alloy occur within a nanometer thin layer at the interface of the solid alloy and the liquid metal. The dealloying forms two distinct phases: one enriched in tantalum that is less soluble in the copper liquid metal and the other enriched in copper. The tantalum-enriched phase forms structures with spacing on the nanometer scale.

Then liquid channels penetrate the material forming a rich variety of structures with different topologies depending on the initial composition of the alloy. This second mechanism is limited by diffusion of the alloy elements to the interface.

These results show that understanding how the nanostructures are formed could lead to the ability to design materials with properties ranging from high surface area to high strength for batteries, nuclear reactors, and other energy applications.

More information: Northeastern University

Comments are closed, but trackbacks and pingbacks are open.