New Standard for Power

Wolfspeed has introduced the first fully-qualified commercial power module from its Fayetteville, Arkansas location. The high-performance 62mm module represents a new generation of all-SiC power modules that enable unprecedented efficiency and power density for high current power electronics, such as: converters/inverters, motor drives, industrial electronics, and high performance electric vehicle systems. The new module allows systems designers to realize lighter weight systems that are up to 67% smaller by achieving efficiencies of over 98% and improvements in power density of up to 10 times compared to systems built with silicon-based technologies.

“Wolfspeed’s launch of this fully-qualified, next-generation SiC power module represents the culmination of an engineering development program that began with the company’s early SiC MOSFET module designs,” explained John Palmour, Wolfspeed’s chief technology officer. “Our 2015 acquisition of Arkansas Power Electronics International (APEI) enabled our team to deliver this advanced power module design on an aggressive timeline by combining leading-edge SiC device technology with the industry’s most advanced wide bandgap packaging innovation. The resulting module is the first of many products that promise an accelerated disruption of the power electronics market.”

“Wolfspeed’s launch of this fully-qualified, next-generation SiC power module represents the culmination of an engineering development program that began with the company’s early SiC MOSFET module designs,” explained John Palmour, Wolfspeed’s chief technology officer. “Our 2015 acquisition of Arkansas Power Electronics International (APEI) enabled our team to deliver this advanced power module design on an aggressive timeline by combining leading-edge SiC device technology with the industry’s most advanced wide bandgap packaging innovation. The resulting module is the first of many products that promise an accelerated disruption of the power electronics market.”

Compared to conventional silicon IGBT power modules, or even previous generations of SiC MOSFET modules, the new module will offer significantly higher power density for applications in which volume and weight are critical limitations. Operating at a higher switching frequency without any compromise in system efficiency means a reduction in the number and size of magnetic and passive components required for the balance of the system. The superior thermal characteristics of SiC devices, along with the packaging design and materials, enable the module to operate at 175°C, which is a key advantage for many industrial, aerospace, and automotive applications.

The newly commercialized Wolfspeed module design is the industry’s most optimized to achieve the unique benefits of SiC technology – with a 66% reduction in module inductance to 5.5nH, compared to competitive power products at 15nH. This reduction in module inductance enables faster switching speeds, higher frequency operation, and ultra-low losses.

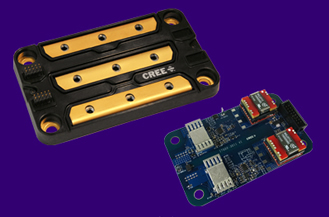

Available as part number CAS325M12HM2, the high performance power module is configured in a half-bridge topology comprised of seven 1.2kV 25mΩ C2M SiC MOSFETs and six 1.2kV 50A Z-Rec Schottky diodes. The companion gate driver (CGD15HB62LP) is specifically designed for integration with the module to fit within the 62mm mounting footprint. An engineering evaluation kit that includes both the module and the gate driver is also available so design engineers can quickly and easily test the performance of the new device in their systems.

Comments are closed, but trackbacks and pingbacks are open.