New Ultra-High-Speed Control IC Technology Maximizes Performance of GaN Devices

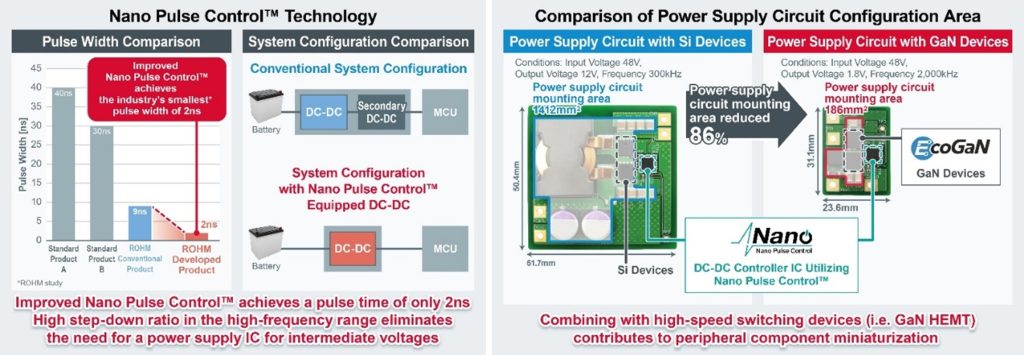

ROHM Semiconductor has introduced ultra-high-speed control IC technology that will enhance the performance of GaN and other high-speed switching devices. The adoption of GaN devices has expanded in recent years due to their superior high-speed switching characteristics. However, the speed of control ICs has become challenging as they are responsible for directing the driving of these devices. In response, ROHM has further developed its ultra-high-speed pulse control technology, Nano Pulse Control™, for power supply ICs, which has improved the control pulse width from the conventional 9ns to an industry-. best 2 ns

ROHM has established its ultra-high-speed control IC technology that maximizes the performance of GaN devices by optimizing Nano Pulse Control technology for GaN devices, leveraging proprietary analog power supply technology. ROHM is currently working to commercialize control ICs utilizing this technology and plans to start sample shipment of a 100V 1ch DC-DC control IC in the second half of 2023. Using this technology in conjunction with ROHM GaN devices (EcoGaN™ series) is expected to result in significant energy savings and miniaturization in a variety of applications, including base stations, data centers, FA (Factory Automation) equipment, and drones.

ROHM’s new control IC technology incorporates Nano Pulse Control, cultivated by combining advanced analog expertise covering circuit design, processes, and layout utilizing ROHM’s vertically integrated production system. This technology significantly reduces the minimum control pulse width of the control IC from the conventional 9ns to 2ns using a unique circuit configuration. Furthermore, it enables a single power supply IC to step down from high voltages up to 60V to low voltages down to 0.6V in 24V and 48V applications. It also supports smaller drive peripheral components for high frequency switching of GaN devices, decreasing mounting area by approximately 86% over conventional solutions when paired with an EcoGaN power supply circuit.

ROHM is developing products that solve social issues by pursuing greater ease-of-use in applications centered on its strengths in analog technology. Professor Yusuke Mori from Osaka University has acknowledged that ROHM has established a mass production system for GaN devices that delivers improved reliability while also developing control ICs that can maximize their performance. Professor Mori has high hopes to contribute to achieving a decarbonized society by collaborating with ROHM’s GaN-on-GaN wafer technology, devices, control ICs, and modules.

In conclusion, the ultra-high-speed control IC technology from ROHM Semiconductor optimizes Nano Pulse Control technology for GaN devices, which results in significant energy savings and miniaturization in various applications. With their expertise in analog technology, ROHM is pursuing greater ease-of-use in applications, and Professor Mori has acknowledged the company’s advancements in this field. The commercialization of this technology is expected to start later this year, and its adoption will enable the industry to take advantage of the superior high-speed switching characteristics of GaN devices.