Novel Thermal Sensor Drives Down Heat

Excess heat from electronic or mechanical devices can cause inefficient performance. Using embedded sensors to monitor heat flow can help alter device behavior or designs to improve efficiency. For the first time, researchers exploited a novel thermoelectric phenomenon to build a thin sensor that visualizes heat flow in real-time. The sensor could be built deep inside devices where other sensors are impractical. It is fast, cheap, and easily manufactured, using well-established methods.

All energy eventually ends as heat, useful when we want to cool something down or get the most out of a battery-driven application. The better we manage the thermal behavior of a device, the better we can engineer around the effect.

Researchers from the Department of Physics at the University of Tokyo looked for new ways to measure heat flux to improve device efficiency and safety, as batteries with poor thermal management can be unsafe. Typical thermal diode devices are relatively large and only give a value for temperature in a specific area rather than an image of the heat flux across an entire surface.

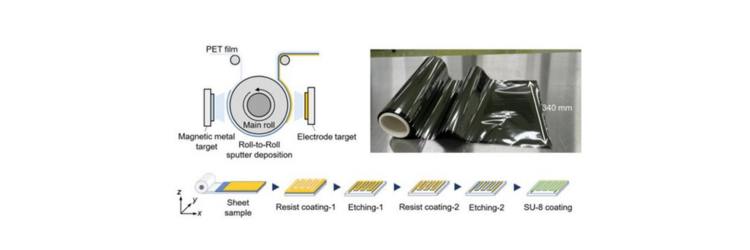

They explored how a heat flux sensor behaves when there are complex heat flow patterns. Magnetic material based on iron and gallium exhibits the anomalous Nernst effect (ANE), where heat energy is unusually converted to an electrical signal. There is also the Seebeck effect, which can create more electrical power, but requires a large bulk of the material, and the materials are brittle and hard to work with. ANE allowed the team to engineer their device on an incredibly thin and malleable sheet of plastic.

The team designed circuits to boost ANE while also suppressing the Seebeck effect, as this interferes with the data-gathering potential of ANE. Previous attempts to do this were unsuccessful, making this sensor the first of its kind.