Plasmatreat has announced that it will start the exhibition year 2020 by attending the IPC APEX EXPO 2020 in San Diego. The trade show will take place from 4th to 6th of February. It is a large electronics manufacturing event in North America, drawing more than 9,000 professionals from 45 countries.

“To us, APEX is an important trade fair in the annual calendar because it allows us to explain to the electronics manufacturing industry the potential of plasma,” explained Hardev Grewal, CEO of Plasmatreat USA, Inc. Even though the plasma technology has long been used in many areas, it is still unknown to many electronics manufacturers.

Plasma is generated when energy is added to a gas by means of electric discharge. This energy input causes atoms to release electrons from their shell. The resulting disassociations lead to the formation of free electrons, ions and molecular fragments. The introduction of the nozzle system developed by Plasmatreat in 1995 made it possible to use this fourth state of matter on an industrial scale.

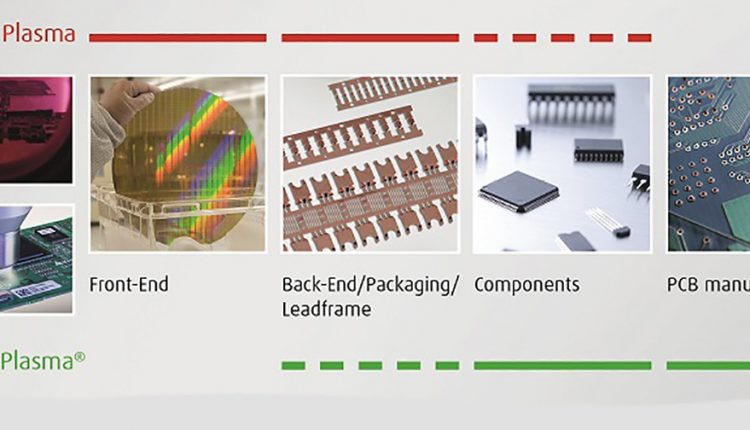

Openair-Plasma is particularly suitable for electronic manufacturing applications which require special surface characteristics for further processing.

Nico Coenen, Business Development Manager Electronics Market at Plasmatreat, explained: “It is used in PCB assembly, display and component manufacturing as well as in potting and sealing applications. As many electronic devices are used in harsh conditions it is essential that a good bonding between all materials is established in order to ensure a long-life time without yield losses in the field. The use of Openair-Plasma is an efficient and cost-effective processes.”

With ever-increasing packing densities and the associated trend for increasing miniaturization, the elevated risk of contaminants causing short-circuits calls for a rethinking of surface treatments. In other areas plasma is used for microfine cleaning contact surfaces – such as bond pads – before wire-bonding, or for cleaning glass surfaces in display manufacturing.

But simultaneous plasma activation is also an important process. Even though circuit boards may look clean, this is no guarantee that the coating will adhere to the PCB.

“Openair-Plasma can really make a big difference here and we see a growing demand for plasma activation before conformal coating,” explained Coenen.

The assumption that atmospheric plasma damages components on the circuit board is incorrect.

Christian Buske, Founder and CEO of Plasmatreat, added:”It is true that for a long-time atmospheric plasma processes could not be used to clean circuit boards due to the risk of short-circuits, which can destroy the finished PCB. But Plasmatreat has developed an Openair-Plasma nozzle specifically for such applications which has been proven to work with a very low, gentle zero-voltage input that does not damage components and layouts.”

Openair-Plasma has proven its worth in electronics manufacturing. The advantages of being selective, running on low operational costs and the fact that users can replace nasty chemical processes are key benefits that are recognized by market leaders around the globe. Every day new applications are discovered with Openair-Plasma.

Plasmatreat will be presenting the Openair-Plasma technology at the IPC APEX EXPO 2020 at booth 527.