A pumped hydro project in southcentral Montana could provide electric utilities in the Pacific Northwest with a US billion-dollar, 400MW facility that mimics both a battery and a fast-start natural gas-fired plant.

The Gordon Butte pumped storage project received its 50-year operating license from the Federal Energy Regulatory Commission in December 2016. The project holds a water right issued by the state of Montana to withdraw water from a nearby stream to fill the project reservoirs, and replace water lost to evaporation and seepage.

According to Carl Borgquist, president and CEO of Bozeman, Montana-based Absaroka Energy, an engineering contract with a design-construction firm is almost complete. But the project is by no means assured.

For one thing, two 40-year-old coal-fired units at the Colstrip power plant in southeastern Montana would need to close as expected in 2022. The closure was agreed to in 2016 by Allentown, Penn.-based Talen Energy and Seattle-based Puget Sound Energy—which own and operate the two units—and environmental groups that sued over air emissions from the 2,094MW plant.

For another thing, at least one of a handful of Pacific Northwest utilities still needs to sign a long-term Purchase Power Agreement (PPA) to buy flexible capacity and ancillary services from the pumped hydro project. That may not be as simple as it sounds: Few U.S. power markets have set a value for the kinds of capacity and ancillary services the project could provide.

What’s more, in a straight-up comparison of installed capacity costs, Gordon Butte loses, according to numbers crunched for Absaroka by the consultancy Energy and Environment Economics, Inc., and presented by Borgquist in February 2017.

The numbers show that the cost per kilowatt for 400MW of pumped hydro capacity is around $2,250. By contrast, the cost for gas-fired capacity—provided by technology that ranges from an aeroderivative combustion turbine to a reciprocating engine—was calculated to be anywhere from $1,217 to $1,650 a kilowatt.

But, says Borgquist, Gordon Butte’s service offerings include what’s known as regulation capacity which could benefit the Pacific Northwest grid. That value is created as the hydro facility cycles between pumping water to its upper reservoir and releasing it in order to spin a turbine generator. This feature effectively doubles Gordon Butte’s capacity to 800MW.

When the value of that regulation capacity is accounted for, Gordon Butte’s cost per kilowatt falls to $1,130. By contrast, the cost is anywhere from $1,177 to $1,830 a kilowatt for the same regulation services provided by a reciprocating engine and aeroderivative.

So, even though Gordon Butte may be more difficult to build than a gas-fired plant, its design adds value by delivering a range of services. “This is just cheaper,” Borgquist said.

Gordon Butte is spec’d to include three Pelton turbines with a total installed generating capacity of 400MW. The turbines are fed by a 70-acre upper reservoir with 312 meters of head (the difference in elevation between the upper and lower reservoirs).

The facility would connect to twin 500kV transmission lines a few kilometers to the south. Known as the Colstrip Transmission System, the corridor links the coal-fired power plant (roughly 370 kilometers by road east of Gordon Butte) to the Bonneville Power Administration’s grid.

A utility with a PPA could use Gordon Butte to provide ancillary services and fast-response capacity. Both services enhance reliability on a grid that is adding large amounts of intermittent renewable resources like wind and solar.

To a casual observer, pumping or releasing water from one reservoir to another through a powerhouse in a closed loop may seem simple. But utilities are conservative by nature and can be shy when it comes to adopting novel technology, said Borgquist.

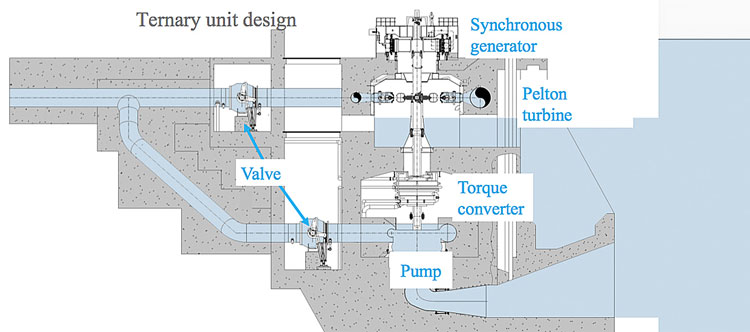

To be sure, pumped hydro is far from novel. Some units in the U.S. were installed 90 years ago. But Gordon Butte would become just the second in the world—and the first in North America—to adopt a ternary pumped hydro configuration. (The Kops II project in Austria serves as a model for Gordon Butte and has been in service since 2009.)

This means Gordon Butte would stack a synchronous generator, a Pelton turbine, a torque converter, and a pump on a single rotating shaft with all of the equipment—supplied by GE Renewable Energy—turning in the same direction.

Unique to the design is a ‘hydraulic short circuit’—basically a hydraulic loop that connects the turbine to the pump. The short circuit makes it possible to switch from pump to generator and back again at an estimated ramp of 20+ MW/second.

Equally novel is the torque converter that is part of the equipment stack and that works essentially like a hydraulic and a mechanical coupling. Using pressure from water downstream of the powerhouse, the torque converter activates the pump without needing to draw power from the grid. Within a minute or so, the pump is up to speed, the mechanical clutch is engaged, and the stack begins to operate with both the pump and the generator engaged.

The rapid switching between pump and generator that is possible in this mode mimics what a storage battery can offer to a grid. Unlike a battery, however, Gordon Butte could cycle back and forth without degrading either its range or its life expectancy.

“For the cost of putting 400MW of pumped storage in the ground, you basically get 800 MW of regulation capacity,” Borgquist said.

Whether or not that offers an enticing business case to utilities remains to be seen.

For example, Puget Sound Energy filed its 2017 Integrated Resource Plan [pdf] with Washington State regulators in mid-November. In it, the utility forecasts a likely need for new renewable and capacity resources by 2022. And it indicates the likelihood that an RFP process could occur in 2018.

One possible resource in that solicitation: Absaroka Energy’s Gordon Butte project.