Researchers combine biology and 3D printing for energy production

New techniques have been developed to extract oil and gas for energy. These advances have made new stores of natural gas, composed mainly of methane, available, but a lot of that methane is leaked, vented or flared during these operations because the gas is difficult to store and transport compared to liquid fuels. Methane is also a major contributor to global warming.

Scientists have now figured out a way to merge the fields of biology and 3D printing in order to create more efficient conversion of methane to energy.

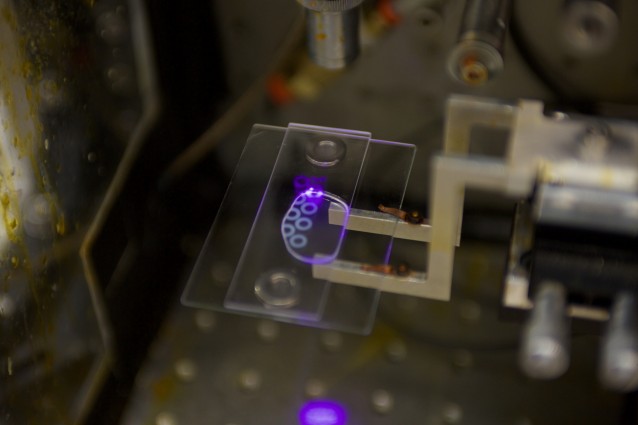

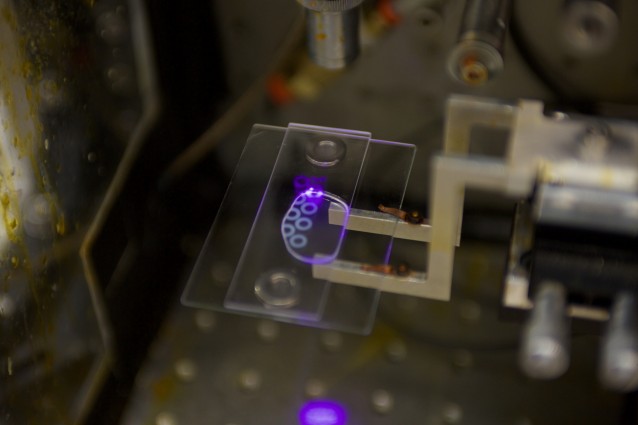

A team from the Lawrence Livermore National Laboratory has created the first reactor that can continuously produce methanol from methane at room temperature and pressure.

In order to do so, the researchers removed enzymes from the bacteria that eat methane, also called methanotrophs, and mixed them with polymers that they printed or molded into reactors.

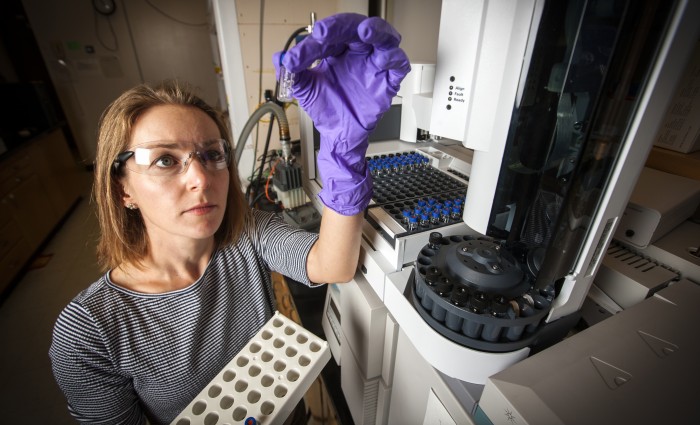

“Remarkably, the enzymes retain up to 100% activity in the polymer,” said Sarah Baker, LLNL chemist and project lead. “The printed enzyme-embedded polymer is highly flexible for future development and should be useful in a wide range of applications, especially those involving gas-liquid reactions.”

Current industrial technologies that convert methane into more valuable products, like steam reformation, operate at high temperature and pressure and require a large number of unit operations. This results in low efficiency of methane conversion and can be costly in the process.

According to the team. a new technology is needed to efficiently convert methane to other hydrocarbons.

Currently, the only known catalyst to convert methane to methanol under ambient conditions with high efficiency is an enzyme called methane monooxygenase (MMO), which converts methane to methanol.

Up until now, most industrial bioreactors are stirred tanks, which can be inefficient for gas-liquid reactions.

“The concept of printing enzymes into a robust polymer structure opens the door for new kinds of reactors with much higher throughput and lower energy use,” said Joshuah Stolaroff, an environmental scientist on the team.

The team found that the 3D-printed polymer could be reused over many cycles and used in higher concentrations than possible with the conventional approach of the enzyme dispersed in solution.

Comments are closed, but trackbacks and pingbacks are open.