Engineers from Massachusetts Institute of Technology have bee working on a band-aid different from the kind you’ve put on your cuts and scrapes in the past.

The water-based Band-Aid they developed is composed of a sticky, stretchy, gel-like material and can include temperature sensors, LED lights, and other electronics — even tiny compartments for storing medication that can be delivered via the bandage.

The “smart wound dressing” could release medicine if a person’s skin temperature changes and can be designed to light up for different reasons (such as low supply of medication in the reservoir.)

These band-aids will conform to the body too. Unlike the ones you may have used, the Band-Aid of the future is composed of a stretchable material that will stretch with parts of the body that bend often, such as the knee or the elbow.

“Electronics are usually hard and dry, but the human body is soft and wet. These two systems have drastically different properties,” said Xuanhe Zhao, Career Development Associate Professor in MIT’s Department of Mechanical Engineering. “If you want to put electronics in close contact with the human body for applications such as health care monitoring and drug delivery, it is highly desirable to make the electronic devices soft and stretchable to fit the environment of the human body. That’s the motivation for stretchable hydrogel electronics.”

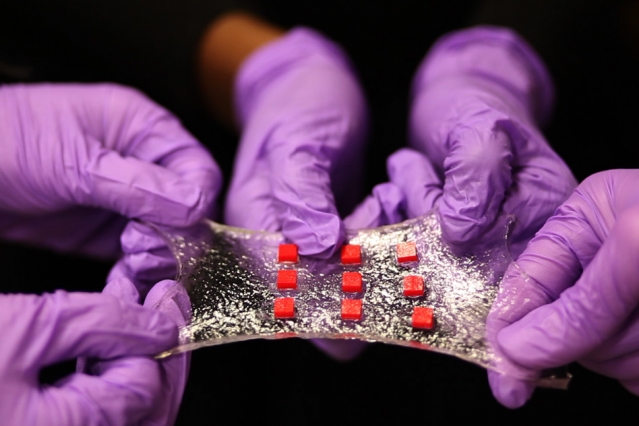

During development, Zhao and the team of engineers embedded different kinds of electronics within the hydrogel, including conductive wires, semiconductor chips, LED lights, and temperature sensors. Zhao discovered that the electronics coated in hydrogel even have potential use inside the body as implants for other medical needs.

Since typical hydrogels are pretty weak, the team designed stronger and more durable hydrogels that could be used for electronics by mixing water with a small amount of selected biopolymers to create soft, stretchy materials with a stiffness of 10 to 100 kilopascals — about the range of human soft tissues. They also figured out how to bond the hydrogel to nonporous surfaces.

Zhao even created an array of LED lights that were embedded in a sheet of hydrogel. He found that when he attached the LED array to parts of the body, even areas that stretched, it continued to work.

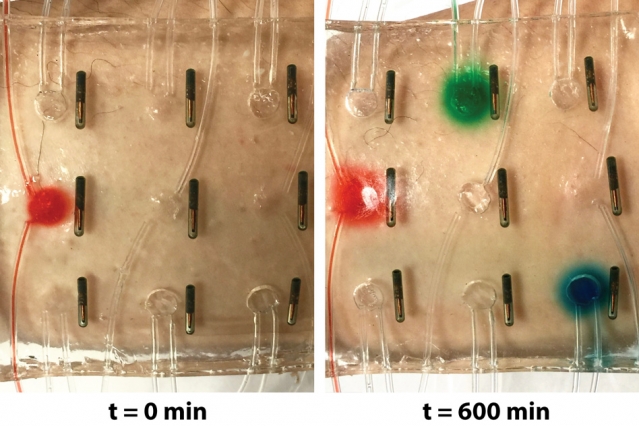

The last part of the device testing and development involved drug administering. The group embedded electronic components within a sheet of hydrogel to create what it called a “smart wound dressing,” which was made up of temperature sensors and tiny drug reservoirs. The team made pathways within the hydrogel for the drugs to flow when certain sensor readings were taken.

The engineers believe this method of drug delivery could potentially be used in the treatment for burns or other skin conditions that require on-demand attention.

Next the team will work on further developing the device for in body use.

“The brain is a bowl of Jell-O,” saud Zhao. “Currently, researchers are trying different soft materials to achieve long-term biocompatibility of neural devices. With collaborators, we are proposing to use robust hydrogel as an ideal material for neural devices, because the hydrogel can be designed to possess similar mechanical and physiological properties as the brain.”

Watch the MIT video below for more information on the new hydrogel electronics.

Story via MIT.

Comments are closed, but trackbacks and pingbacks are open.