A research team from Missouri University of Science and Technology has demonstrated a printer that requires no ink.

Of course, you’ll need a high-powered electron microscope to read the print.

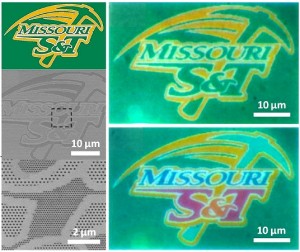

The researchers exemplify their “no-ink” printing method by using the Missouri S&T school logo on a nanometer-scale surface.

Their methods, published in the latest issue of the Nature Publishing Group journal, “involve the use of thin sandwiches of nanometer-scale metal-dielectric materials known as metamaterials that interact with light in ways not seen in nature.”

The researchers experimented with white light on plasmonic interfaces to developed what they call “a simple but efficient structural color printing platform” at the nanometer-scale level.

Future applications for such processes include nanoscale visual arts, security marking and information storage.

How it works

The printing surface is made up of a sandwich-like structure with two thin films of silver separated by a “spacer” film of silica. The top layer of silver film is 25 nanometers thick and punctured with tiny holes created by a microfabrication process called focused ion beam milling. The bottom layer of silver is four times thicker than the top layer but still minuscule at 100 nanometers. Between the top and bottom films lies a 45-nanometer silica dielectric spacer.

Then the team took the school logo and shrunk it down so that it looked like a needlepoint logo under a scanning electron microscope. By simply beaming light through the perforated holes, they were able to recreate the logo.

When they adjusted the hole size of the top layer they were able to create different colors in the reflected light in order to accurately reproduce the S&T athletic logo with nanoscale color palettes.

“Unlike the printing process of an inkjet or laser jet printer, where mixed color pigments are used, there is no color ink used in our structural printing process – only different hole sizes on a thin metallic layer,” says Dr. Jie Gao, an assistant professor of mechanical and aerospace engineering at Missouri S&T and a co-author of the paper.

With such technology, the future could be “high-performance, pigment-free color printing.”