Researchers make a ceramic 3D-printing breakthrough

Research-and-development company, HRL Laboratories, has just announced that its scientists have achieved a new milestone in 3D printing technology by demonstrating an approach to create ceramics via a 3D printing process that overcomes the limits of traditional ceramic processing and enables high temperature, high strength ceramic components.

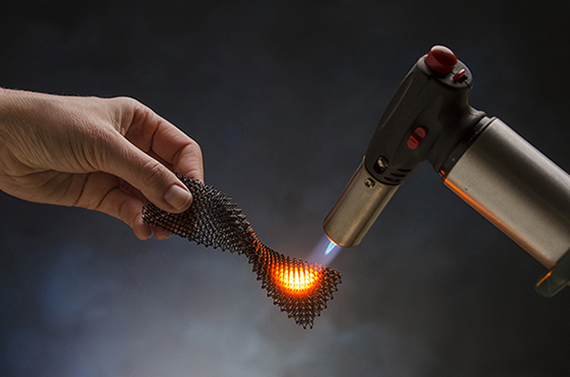

Senior Chemical Engineer, Zak Eckel, and Senior Chemist, Dr. Chaoyin Zhou, invented a resin formulation that can be 3D-printed into parts of any shape or size. The printed resin can then be fired which transforms it into a high-strength, fully dense ceramic. The resulting material can withstand temperatures over 3,000°F and exhibits strength 10 times higher than similar materials.

As you may imagine, 3D printing ceramics is a much more difficult process than the 3D printing of polymers or metals because they cannot be cast or machined easily. Typically the ceramic parts are consolidated from powders by a process called sintering, which makes it more porous and limits both achievable shapes and final strength.

“With our new 3D printing process we can take full advantage of the many desirable properties of this silicon oxycarbide ceramic, including high hardness, strength and temperature capability as well as resistance to abrasion and corrosion,” said Dr. Tobias Schaedler, program manager at HRL Laboratories.

The team’s new process and material could be used in a wide range of applications, including the development of large components for jet engines and hypersonic vehicles to parts in microelectromechanical systems and electronic device packaging.

Watch the video below for more information.

Comments are closed, but trackbacks and pingbacks are open.