Researchers make safer lithium-ion batteries by inserting sensors

Lithium-ion (Li-ion) batteries are commonly used in many of our daily-use devices like laptops, cellphones, and iPods, as well as in airplanes and electric cars. While their small and lightweight features make them ideal as a power source, recent events have shown that Li-ion batteries come along with certain dangers.

For example, a recent battery fire occurred aboard a Boeing Dreamliner last year and presently some hoverboards are struggling with Li-ion battery safety issues.

Researchers from Penn State’s Battery and Energy Storage Technology (BEST) Center have been working to make the lithium-ion (Li-ion) batteries we use every day safer by inserting warning sensors to alert users to potential problems inside the battery.

“Li-ion batteries essentially provide portable power for everything,” said Chao-Yang Wang, William E. Diefenderfer Chair of Mechanical Engineering and professor of mechanical engineering, chemical engineering, and materials engineering.

Within traditional Li-ion batteries is a flammable electrolyte solution that under normal circumstances is not dangerous. However, if the battery is punctured or overcharged, a problem called thermal runaway can occur which can cause the battery to overheat and the battery pack catch on fire.

“Your cell phone charge can now last for a week instead of a day, but it’s still the same size. The battery has a lot more energy density, you are compressing more and more energy into a smaller space, and you have to be careful when you do that,” said Wang. “Our job is to come up with solutions to provide safety while at the same time increasing performance.”

By inserting temperature sensors into Li-ion batteries to monitor internal temperatures, a technology referred to as internal reaction temperature sensing (RTS), the Penn State researchers are hoping to add new levels of safety, allowing for early detection of problems and provide warning for intervention.

“We have a unique capability to put sensors inside of cells,” said Chris Rahn, professor of mechanical engineering. “It’s an emerging area and we are on the forefront.”

Instead of just waiting for the battery to generate enough heat from the inside and use an external sensor, which can take a long time due to the battery case, RTS monitors the temperatures on the inside so it can detect issues more quickly. If the sensor detects that the inside is too hot, it will shut down the current flow in the battery.

Penn State was the first university to make large-format Li-ion cells in the lab and it’s that technology that allows researchers to insert and test these sensors.

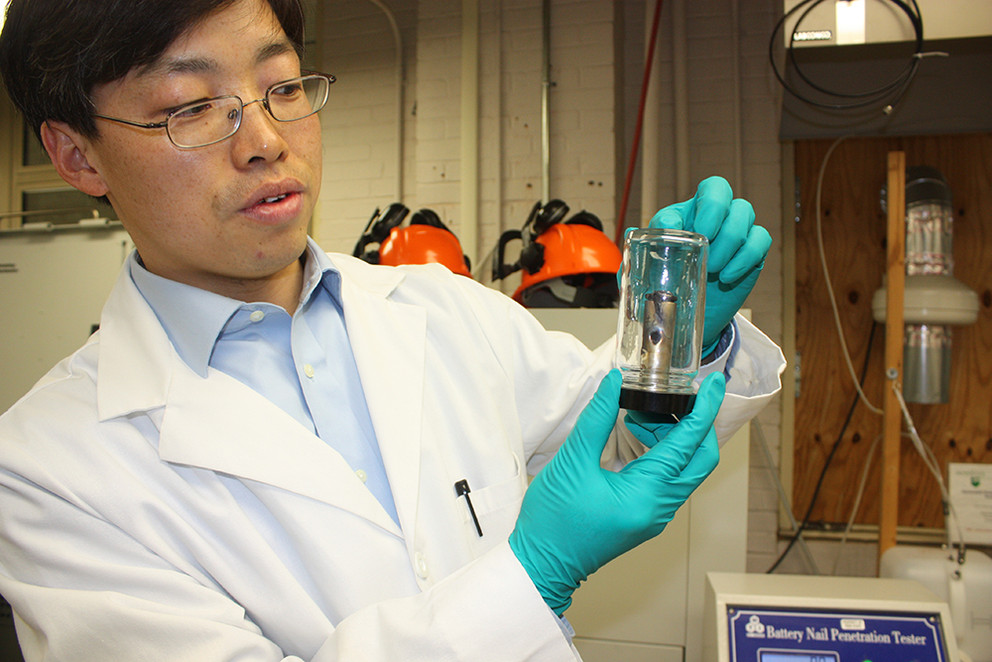

“We make the batteries in our lab and then test them in our lab,” said Guangsheng Zhang, research associate in mechanical engineering. “Very few universities have the capabilities to make their own batteries.”

The team is working on the new technology in an attempt to get one step closer to a larger goal: smart batteries equipped with built-in sensors and actuators to enhance battery performance, life, and safety. Battery operators would not only be able to detect what is happening inside the battery, but also change the internal state of the battery (for example heating a battery so that it would work in extreme cold).

Story via Penn State University.

Comments are closed, but trackbacks and pingbacks are open.