Revolutionary Approach to Fire Manipulation Enabled by Nanoscale Material

High-temperature flames are used to create a wide variety of materials – but once you start a fire, it’s not always easy to control how it interacts with the process. Researchers have now developed a technique that utilizes a molecule-thin protective layer to do so – taming the fire and allowing users to fine-tune the processed material’s characteristics.

“Fire is a valuable engineering tool – after all, a blast furnace is only an intense fire,” says Martin Thuo, corresponding author of a paper on the work and a professor of materials science and engineering at North Carolina State University. “However, once you start a fire, you often have little control over how it behaves.

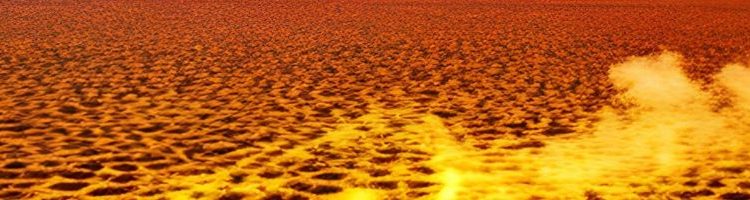

Here’s how ITD works. You start with your target material, such as cellulose fiber, then coat it with a nanometer-thick layer of molecules. The coated fibers are then exposed to an intense flame. The outer surface of the molecules combusts easily, raising the temperature in the immediate vicinity. As the heat rises, the inner surface of the molecular coating chemically changes, creating an even thinner layer of glass around the cellulose fibers.

This glass limits the amount of oxygen that can access the threads, preventing the cellulose from bursting into flames. Instead, the fibers smolder – burning slowly from the inside out.

“We can engineer the protective layer to tune the amount of oxygen that reaches the target material. And we can engineer the target material to produce desirable characteristics.”

The researchers could control the thickness of the carbon tube walls by controlling the size of the cellulose fibers they started with, introducing various salts to the threads (which further slows the burning rate), and varying the amount of oxygen that passes through the protective layer.

“We have several applications in mind already, which we will address in future studies,” Thuo says. “We’re also open to working with the private sector to explore various practical uses, such as developing engineered carbon tubes for oil-water separation – which would be useful for both industrial applications and environmental remediation.”