How To Save Time And Improve Productivity With Signal Conditioner

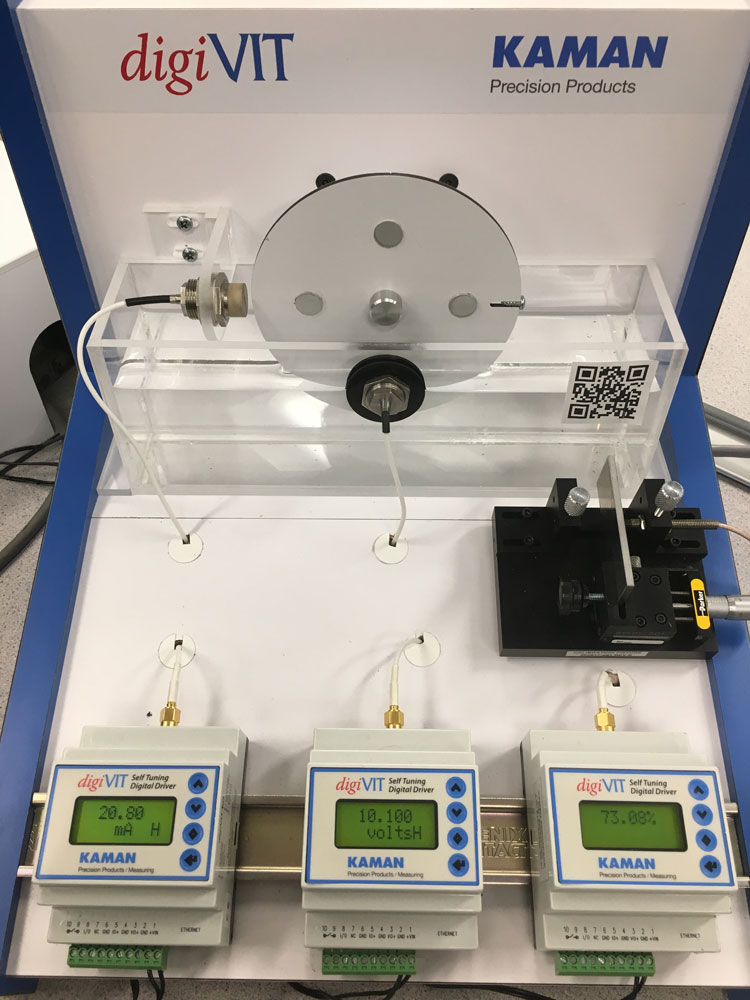

The Measuring Division of Kaman Precision Products has announced the digiVIT digital variable impedance transducer.

The user-friendly Graphical User Interface allows for easier set-up, connectivity and cloud-based data access/monitoring.

The digiVIT offers a wide array of networking capabilities suitable for Industrial Internet of Things (IIoT) applications.

It is a good choice for position, vibration, and proximity sensing, part sorting, process control, laboratory testing, engine dynamics testing, and condition monitoring.

The digiVIT is what the company claims to be the most advanced digital signal conditioner for non-contact linear position and displacement sensing.

![How To Save Time And Improve Productivity With Signal Conditioner]() The self-configuring system

The self-configuring system

It is capable of performing with nearly any sensor, from any manufacturer, as well as any conductive target.

The transducer features simple pushbutton calibration, temperature compensation, and zeroing.

The digiVIT features scrolling menus for intuitive set-up and calibration, as well as Ethernet communication capabilities.

In addition, it is capable of detecting when no sensors or shorted sensors are present.

The large integral digital display makes it easy for users to read all of the transducer’s information.

Self-optimization capabilities ensure the best performance possible for any combination of sensor, target, cable and calibration.

The digiVIT’s embedded intelligence ensures that all functions are accessible.

There is no need to connect to a PC to download a configuration file when changing sensors or performing high level calibrations.

Comments are closed, but trackbacks and pingbacks are open.